Jacob Noble

- 3

- 0

- TL;DR

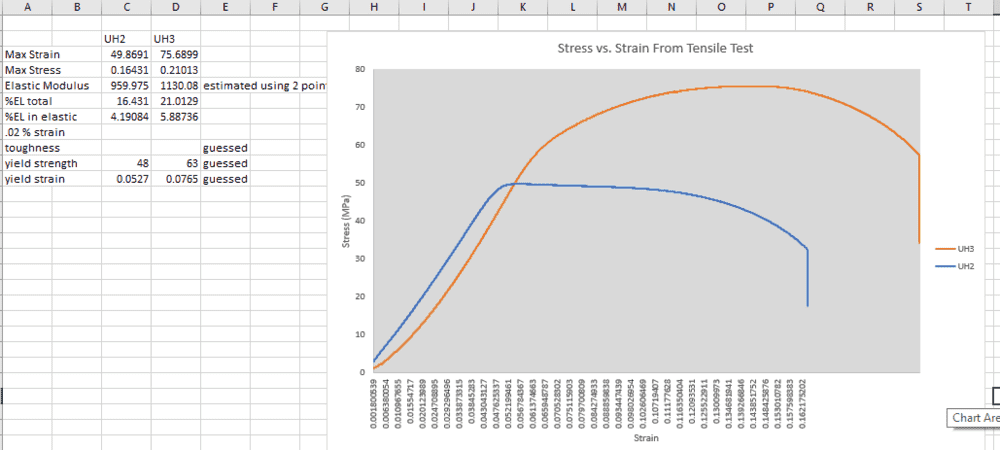

- Tensile tested 2 samples of 1018 unheat treated carbon steel, assumed to be very similar steel (bought from same place, same order, ect) very different tensile test results.

Tensile tested 2 samples of 1018 unheat treated carbon steel, assumed to be very similar steel (bought from same place, same order, ect) but very different tensile test results.

The results of the tensile test can be seen below as well as a few calculated values. I do not know what this would be from as the samples were tested on same machine with changing settings (re balanced), one after the other, measurements taken from same spots.

The results of the tensile test can be seen below as well as a few calculated values. I do not know what this would be from as the samples were tested on same machine with changing settings (re balanced), one after the other, measurements taken from same spots.