- #1

kunalvanjare

- 80

- 2

Hello,

We make a Venturi vacuum system for recovering CNC coolant from the swarf trolley. It is a simple arrangement consisting of a venturi tube tee'd off the coolant pump and a stand-off placed at the bottom of the swarf trolley with a filter disc.

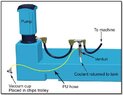

Now the problem with this system is that it is dedicated to each machine, where pressurized coolant passes through the venturi from the pump (motive) and creates a suction through which coolant is sucked from the swarf trolley. Coolant that passes through the venturi is returned to the sump. A schematic is attached for reference.

Now, I have had multiple clients ask for a similar portable system. But I can't for the life of me figure out how! I could use compressed air or even a Turbine Blower to generate the vacuum in the venturi, but the sucked coolant will mix with this air on the outlet of the venturi. How do I avoid this?

Thanks,

KV

We make a Venturi vacuum system for recovering CNC coolant from the swarf trolley. It is a simple arrangement consisting of a venturi tube tee'd off the coolant pump and a stand-off placed at the bottom of the swarf trolley with a filter disc.

Now the problem with this system is that it is dedicated to each machine, where pressurized coolant passes through the venturi from the pump (motive) and creates a suction through which coolant is sucked from the swarf trolley. Coolant that passes through the venturi is returned to the sump. A schematic is attached for reference.

Now, I have had multiple clients ask for a similar portable system. But I can't for the life of me figure out how! I could use compressed air or even a Turbine Blower to generate the vacuum in the venturi, but the sucked coolant will mix with this air on the outlet of the venturi. How do I avoid this?

Thanks,

KV