Frikiflax

- 3

- 0

Hi Folks! I'm new here and need your help.

I`m in the process of designing an alt azimuth mount for a Heliostat. For those of you who don't know a Heliostat is a mechanism that allows a mirror to rotate around the vertical axis(horizon) and horizontal axis(altitude). It is(usually) placed outdoors and let's you control the direction in which the sunlight is reflected by the mirror by tracking the position of the sun in the sky. Here is a picture of such a device:

This particular design would be ideal for me but I don`t have the tools to make it. This is a personal project and I've decided to build the whole thing myself, therefore my budget is quite limited. The thing is that I want to build three heliostats, each one will support a round glass mirror that will be about 1,2 meters in diameter. I have estimated the weight of the mirrors to be around 8 kilograms each.

My problem is the following: The starting point of the heliostat design is deciding what motor and gear configuration to use. I would like to use the smallest stepper motor posible, I'm looking at https://oceancontrols.com.au/MOT-120.html because they are cheap and easy to control. They are pretty standard CNC machine steppers.

Now comes the second problem: Speed and Power. Since heliostats are placed outdoors the mirrors are subject to the forces of the wind and it's important that they hold their position steadily.

Another factor to consider is that since the sun moves slowly across the sky I don`t need the heliostat to rotate quickly. Instead I need the Heliostats to be very precise since the target they will point the sun's reflection to will be located at about 200 meters away.

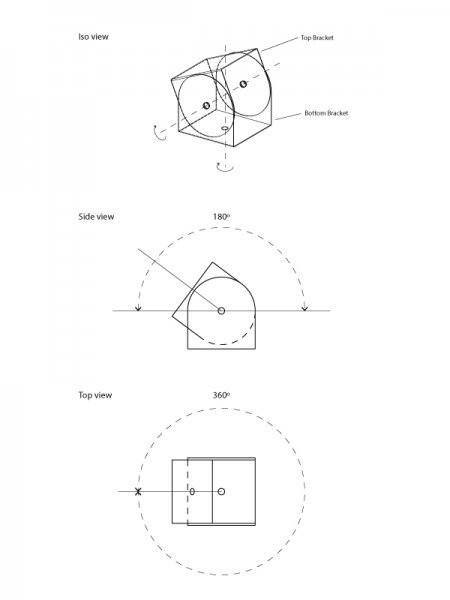

The heliostat design that I've come up with(given the tools at my disposal) involves two metal brackets. The bottom bracket will rotate at a 360º around the vertical axis. The top bracket will be mounted on the bottom bracket and will rotate at a 180º around the horizontal axis. Like this:

The mirror will be mounted on top of the top bracket.

With all that in mind I think I have to gear choices to move these things: Timing belts or worm gears made out of Technyl plastic(Polyamide)

Worm Drive

PROS:

- Very precise control of rotation with high torque and smooth movement.

- Simpler than timing belts since only one per axis is required

- Strong

- Holds its position: I can have the worm gear machined in such a way to be self-locking. That way even if the heliostat is subject to strong winds it will not be able to force the stepper motor out of its position.

CONS:

- Friction: I am not sure if the friction needed to rotate the worm gear will be low enough for the steppers I intend to use. (Even if its made of Technyl)

- More expensive than timing belts

Timing Belts

PROS:

- Cheap: I can 3d print all the pulleys.

- Can be made very precise

- Very little friction

- Lighter

CONS:

- More complicated to setup since they will require more pulleys and bearings in order to be as precise as a worm drive.

- Not as strong as worm drive

- Not self locking

Given the context that I just described, Which gear choice would you recommend? Am I using the correct stepper motor? I would like to use the worm drive but I am not sure the friction needed for its rotation would cause the motor to overheat.

Thanks a lot!

pd: Geez I ended up writing a lot more than I expected, Sorry! I just want to make the problem as clear as possible so you guys can help me.

Disclaimer: I am not an engineer. I am actually an industrial designer with a passion for machines :D

I`m in the process of designing an alt azimuth mount for a Heliostat. For those of you who don't know a Heliostat is a mechanism that allows a mirror to rotate around the vertical axis(horizon) and horizontal axis(altitude). It is(usually) placed outdoors and let's you control the direction in which the sunlight is reflected by the mirror by tracking the position of the sun in the sky. Here is a picture of such a device:

This particular design would be ideal for me but I don`t have the tools to make it. This is a personal project and I've decided to build the whole thing myself, therefore my budget is quite limited. The thing is that I want to build three heliostats, each one will support a round glass mirror that will be about 1,2 meters in diameter. I have estimated the weight of the mirrors to be around 8 kilograms each.

My problem is the following: The starting point of the heliostat design is deciding what motor and gear configuration to use. I would like to use the smallest stepper motor posible, I'm looking at https://oceancontrols.com.au/MOT-120.html because they are cheap and easy to control. They are pretty standard CNC machine steppers.

Now comes the second problem: Speed and Power. Since heliostats are placed outdoors the mirrors are subject to the forces of the wind and it's important that they hold their position steadily.

Another factor to consider is that since the sun moves slowly across the sky I don`t need the heliostat to rotate quickly. Instead I need the Heliostats to be very precise since the target they will point the sun's reflection to will be located at about 200 meters away.

The heliostat design that I've come up with(given the tools at my disposal) involves two metal brackets. The bottom bracket will rotate at a 360º around the vertical axis. The top bracket will be mounted on the bottom bracket and will rotate at a 180º around the horizontal axis. Like this:

The mirror will be mounted on top of the top bracket.

With all that in mind I think I have to gear choices to move these things: Timing belts or worm gears made out of Technyl plastic(Polyamide)

Worm Drive

PROS:

- Very precise control of rotation with high torque and smooth movement.

- Simpler than timing belts since only one per axis is required

- Strong

- Holds its position: I can have the worm gear machined in such a way to be self-locking. That way even if the heliostat is subject to strong winds it will not be able to force the stepper motor out of its position.

CONS:

- Friction: I am not sure if the friction needed to rotate the worm gear will be low enough for the steppers I intend to use. (Even if its made of Technyl)

- More expensive than timing belts

Timing Belts

PROS:

- Cheap: I can 3d print all the pulleys.

- Can be made very precise

- Very little friction

- Lighter

CONS:

- More complicated to setup since they will require more pulleys and bearings in order to be as precise as a worm drive.

- Not as strong as worm drive

- Not self locking

Given the context that I just described, Which gear choice would you recommend? Am I using the correct stepper motor? I would like to use the worm drive but I am not sure the friction needed for its rotation would cause the motor to overheat.

Thanks a lot!

pd: Geez I ended up writing a lot more than I expected, Sorry! I just want to make the problem as clear as possible so you guys can help me.

Disclaimer: I am not an engineer. I am actually an industrial designer with a passion for machines :D