JCJones

- 5

- 0

For a piece of coursework I have to design a shaft for a windturbine.

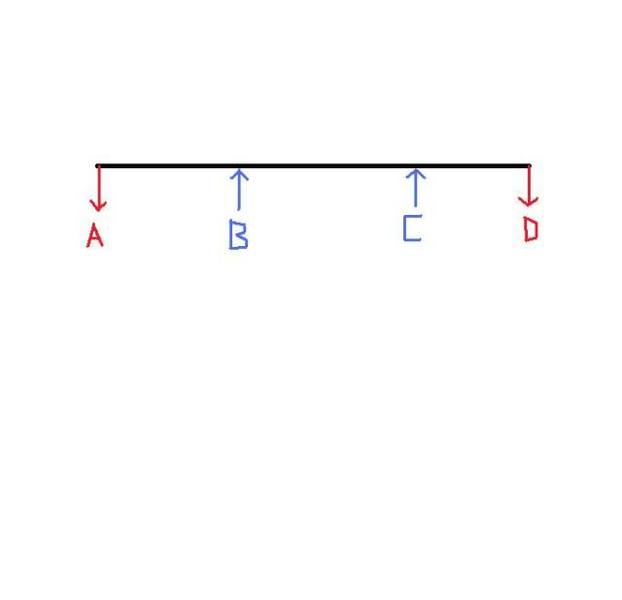

The shaft has a load on one end due to the rotor blades and a load on the opposite end due to a sprocket which is chain linked to a generator. The supports are bearings in between the two loads, as shown in this drawing:

A is the force due to the rotor: 343.35N

B is a bearing/support

C is the second bearing/support

D is the force due to the chain: 781.46N

My task at this point is to locate the bearings on the shaft and then specify which bearings to use.

However I can't work out how to calculate the reaction forces at the supports. I've been trying to do it using the usual: sum of forces in y direction=0 and sum of the moments=0 but I keep ending up with one support taking more load than the sum of the y forces and the second support therefore being negative, as if it is another load.

Due to the constraints of a frame the beam has to be attached to, the first support(B) is 60mm from the rotor(A) and the second support(C) is 40mm from the sprocket(D). The shaft is 350mm long.

If anyone can point out where I might be going wrong it would be a massive help!

The shaft has a load on one end due to the rotor blades and a load on the opposite end due to a sprocket which is chain linked to a generator. The supports are bearings in between the two loads, as shown in this drawing:

A is the force due to the rotor: 343.35N

B is a bearing/support

C is the second bearing/support

D is the force due to the chain: 781.46N

My task at this point is to locate the bearings on the shaft and then specify which bearings to use.

However I can't work out how to calculate the reaction forces at the supports. I've been trying to do it using the usual: sum of forces in y direction=0 and sum of the moments=0 but I keep ending up with one support taking more load than the sum of the y forces and the second support therefore being negative, as if it is another load.

Due to the constraints of a frame the beam has to be attached to, the first support(B) is 60mm from the rotor(A) and the second support(C) is 40mm from the sprocket(D). The shaft is 350mm long.

If anyone can point out where I might be going wrong it would be a massive help!