freshcoast

- 185

- 1

1. Problem statement

A simple model of a crane involves a motor driven drum that winds or unwinds a steel cable onto the drum. The cable passes through a pair of guides and over a pulley at the end of the crane arm. Ignore the mass of the cable in your calculations. The drum has a mass of 650kg and a 1.4m radius. The pulley has a radius of 85 cm and a mass of 295kg. The load has a mass of 1800kg.

a) if the load is to be accelerated from rest to a constant lifting speed of 30cm/s over a distance of 10cm, what minimum torque must the motor provide?

b) what minimum amount of energy is required by the motor to lift the load from rest to a final height of 10m where it ends at rest?

c) what are the tensions in the section of cable from the drum to the pulley, and from the pulley to the load as the load is accelerated? What are the tensions when the load is lifted at constant speed?

2. Related equations

Rotation equations

Torque equations

Moment of inertial equation

3. Attempt at solution

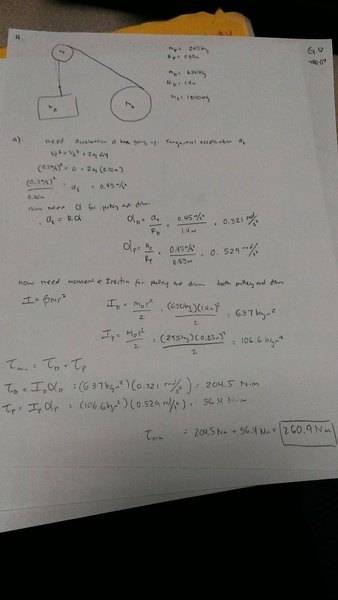

For part a) what I did so far is I know there is a linear tangential equation that the load is lifted at a distance of .1m which I solved using Newtons kinematic then I converted that to a rotational acceleration by dividing it by the radius of each of the pulley and the drum. Which gives me two different alphas, I then find the moment of inertia for the drum and the pulley which then I can find the torques for each. So since I found the torques do I just sum those up and it will give me the minimum torque needed? But my question is how do I count for the mass of the load? Or is my answer correct?

Part b) since the load is starting from rest and ends at rest, wouldn't the kinetic energy equal to 0? Meaning that the total work done would just be the change in potential energy of the mass? But my professor was saying that the easiest way to go about this is that there is 3 stages that the box goes through, which is an acceleration stage, a constant speed stage and a deceleration stage, and then I just integrate the torque by the main drum by the 3 arc lengths that the box goes through? I don't know how to go about doing that, and the one last way that I was suggested is find the rotational kinetic energy for the pulley and the drum and sum those up with the potential energy of the load? I don't know which is the correct way of going about this question..

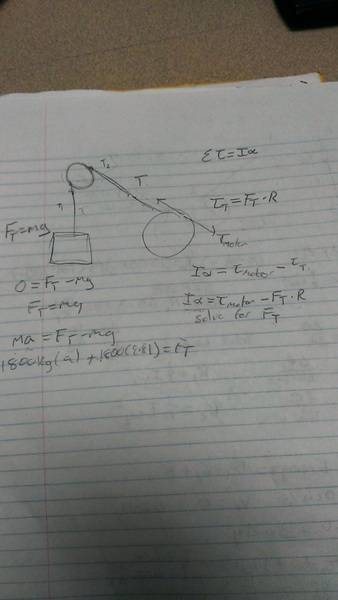

Part c) I know the tension from pulley to the load is the easy part since I'm just summing up the forces in the y direction when there is an acceleration or not , but from the drum to the pulley, do I just apply the summation of the torque ( when being accelerated ) is I(alpha) = torque(motor) - torque(tension) where torque(tension) is equal to Ft*r and just solve for ft since I have found most of the values already.

Thanks for any input and sorry for the long read!

Thanks for any input and sorry for the long read!

A simple model of a crane involves a motor driven drum that winds or unwinds a steel cable onto the drum. The cable passes through a pair of guides and over a pulley at the end of the crane arm. Ignore the mass of the cable in your calculations. The drum has a mass of 650kg and a 1.4m radius. The pulley has a radius of 85 cm and a mass of 295kg. The load has a mass of 1800kg.

a) if the load is to be accelerated from rest to a constant lifting speed of 30cm/s over a distance of 10cm, what minimum torque must the motor provide?

b) what minimum amount of energy is required by the motor to lift the load from rest to a final height of 10m where it ends at rest?

c) what are the tensions in the section of cable from the drum to the pulley, and from the pulley to the load as the load is accelerated? What are the tensions when the load is lifted at constant speed?

2. Related equations

Rotation equations

Torque equations

Moment of inertial equation

3. Attempt at solution

For part a) what I did so far is I know there is a linear tangential equation that the load is lifted at a distance of .1m which I solved using Newtons kinematic then I converted that to a rotational acceleration by dividing it by the radius of each of the pulley and the drum. Which gives me two different alphas, I then find the moment of inertia for the drum and the pulley which then I can find the torques for each. So since I found the torques do I just sum those up and it will give me the minimum torque needed? But my question is how do I count for the mass of the load? Or is my answer correct?

Part b) since the load is starting from rest and ends at rest, wouldn't the kinetic energy equal to 0? Meaning that the total work done would just be the change in potential energy of the mass? But my professor was saying that the easiest way to go about this is that there is 3 stages that the box goes through, which is an acceleration stage, a constant speed stage and a deceleration stage, and then I just integrate the torque by the main drum by the 3 arc lengths that the box goes through? I don't know how to go about doing that, and the one last way that I was suggested is find the rotational kinetic energy for the pulley and the drum and sum those up with the potential energy of the load? I don't know which is the correct way of going about this question..

Part c) I know the tension from pulley to the load is the easy part since I'm just summing up the forces in the y direction when there is an acceleration or not , but from the drum to the pulley, do I just apply the summation of the torque ( when being accelerated ) is I(alpha) = torque(motor) - torque(tension) where torque(tension) is equal to Ft*r and just solve for ft since I have found most of the values already.