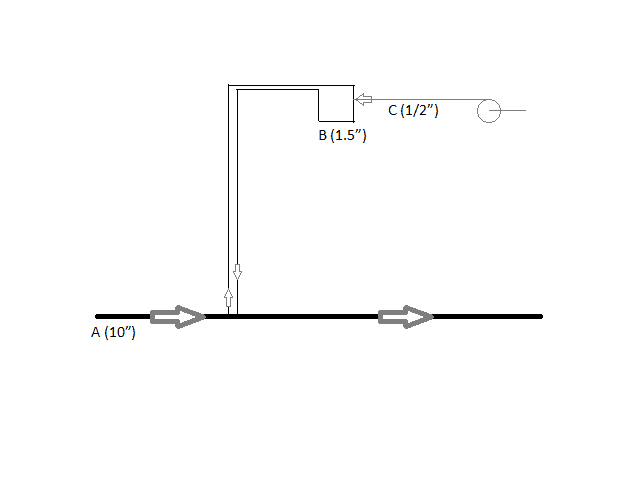

He was suggesting that you put an orifice in the 10" pipe, to increase it's pressure loss between the inlet and outlet of the mixing header.

An orifice does the same as a control valve would, it restricts the flow path to increase head loss; except that it isn't variable. Ideally, you'd match the loss over the orifice to the expected flow rate (based on orifice size and header pressure and current demand flow) with the expected flow rate and pressure drop along the 1.5" header. You'd have a bear of a time getting any specific flow rate, but with a couple valves that you can hand-modulate, you could probably get it to work assuming upstream and downstream pressures remain relatively constant.

The problem is that you generally don't want to make unnecessary drops in line pressure, especially on mains. Your downstream users will not be happy about it and if this is an operating facility, you'll have to make sure that all equipment downstream of the orifice will be operating properly (maybe they'd have to be adjusted) with a lower feed pressure and (likely) flow rate. How drastic this would be depends on how much flow you need in that pipe and what the expected head loss there is, if all you need is like 20 gpm, then you could install an orifice that, at your expected mains flow and pressure, would dissipate something like 2 psi.

Whether it's more economical to leave what you've got an install some heat tape and insulation (and have somewhat higher upfront costs plus some additional operating expense in the winter for the electricity) or have lower upfront costs, but have to deal with reduced line pressure and likely line flows (slightly), or do something else; well, that's something you'll have to look into.

**btw, by explaining everything as I am I don't mean to seem like I'm assuming you don't know anything. It's just that I tend to answer questions assuming someone else will look at it later and potentially learn something.