- #1

Will Flannery

- 114

- 34

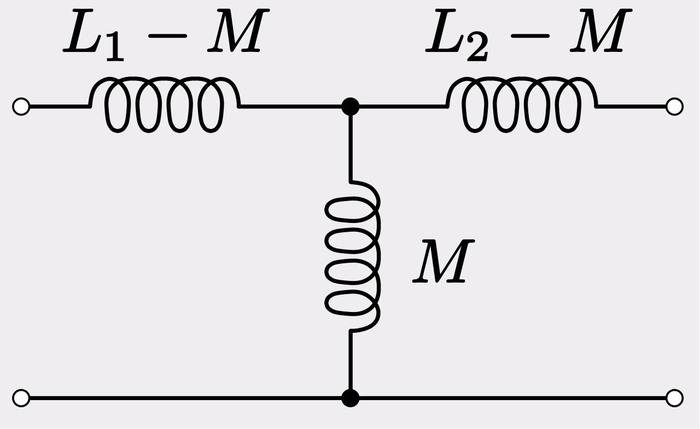

My goal is to program a FDM simulation of a transformer. So, we have the coupled inductor model to start with ...

However, if L1 = 1, L2 = 9, and coupling is perfect then M = sqrt(1*9) = 3 and L1 - M = -2.

So, this seems problematical to me. Also, if I try to simulate this model using SPICE, just for fun you understand, my goal is to program the sim myself, SPICE chokes on the negative inductor value and no output signal is generated.

I note that the model above does produce the right differential equations, that is, v1 = L1*i1' + M*i2' v2 = L2*i2' + M*i1'

However, if you try to simulate these differential equations directly, and the coupling is perfect, the the ratio L1 / M = M / L2 = sqrt(L1) / sqrt(L2) and you cannot solve them for i1' and i2'. So, I'm stuck starting with these differential equations too.

One more thing - running the SPICE transformer model, i.e. specifying L1 = 1, L2 = 9, and k = 1, with a 1 v. 60 Hz input produces the expected 3 v. output. However, changing k to .9 reduces the output to a few mv. Even .99 and its still a few mv. That seems very peculiar to me (I'm not an EE).

However, if L1 = 1, L2 = 9, and coupling is perfect then M = sqrt(1*9) = 3 and L1 - M = -2.

So, this seems problematical to me. Also, if I try to simulate this model using SPICE, just for fun you understand, my goal is to program the sim myself, SPICE chokes on the negative inductor value and no output signal is generated.

I note that the model above does produce the right differential equations, that is, v1 = L1*i1' + M*i2' v2 = L2*i2' + M*i1'

However, if you try to simulate these differential equations directly, and the coupling is perfect, the the ratio L1 / M = M / L2 = sqrt(L1) / sqrt(L2) and you cannot solve them for i1' and i2'. So, I'm stuck starting with these differential equations too.

One more thing - running the SPICE transformer model, i.e. specifying L1 = 1, L2 = 9, and k = 1, with a 1 v. 60 Hz input produces the expected 3 v. output. However, changing k to .9 reduces the output to a few mv. Even .99 and its still a few mv. That seems very peculiar to me (I'm not an EE).