flashskate13

- 4

- 1

Hello All,

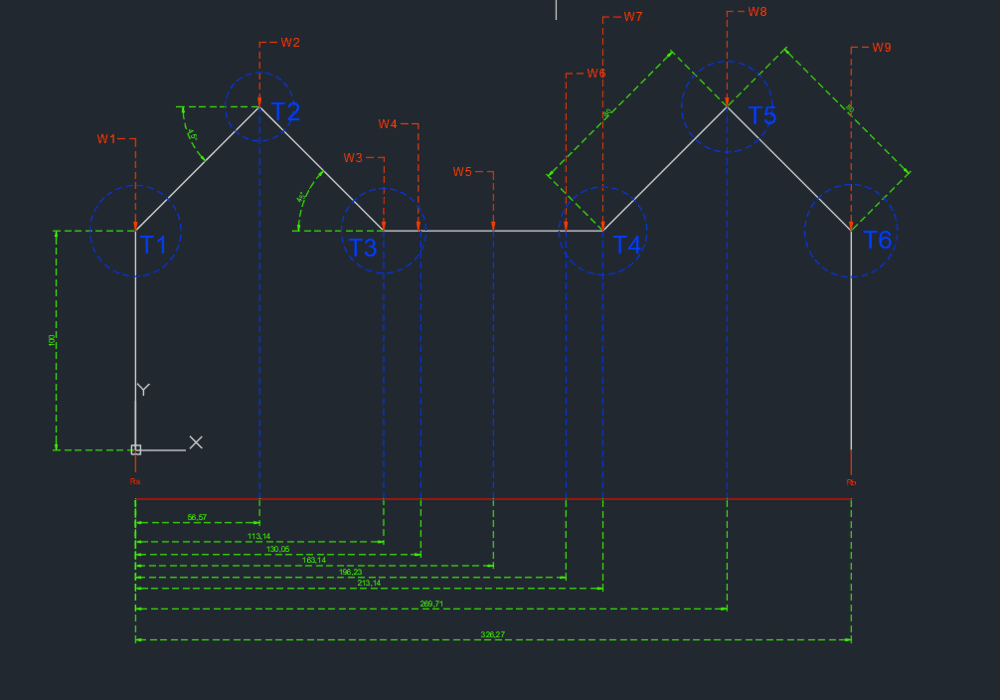

I am designing a robot that has these dimensions, I need to work out the torques around T1 to T6, I am unsure of the best way to do it, ie do I do a net torque calculation around the torque to be found or is there a better way.

W1 to W4 =

W5 =

W6 to W9 =

The arms that measure 100mm are currently drawn at 90 degrees but these will probably be more 89 degree.

I'm looking at getting the most accurate results this is a new subject to me, and I understand the basics of torque and reactions but don't know how to piece it together for the case.

I am designing a robot that has these dimensions, I need to work out the torques around T1 to T6, I am unsure of the best way to do it, ie do I do a net torque calculation around the torque to be found or is there a better way.

W1 to W4 =

0.53955 kN |

14.44032 kN |

1.0791 kN |

I'm looking at getting the most accurate results this is a new subject to me, and I understand the basics of torque and reactions but don't know how to piece it together for the case.