iamasponge

- 2

- 0

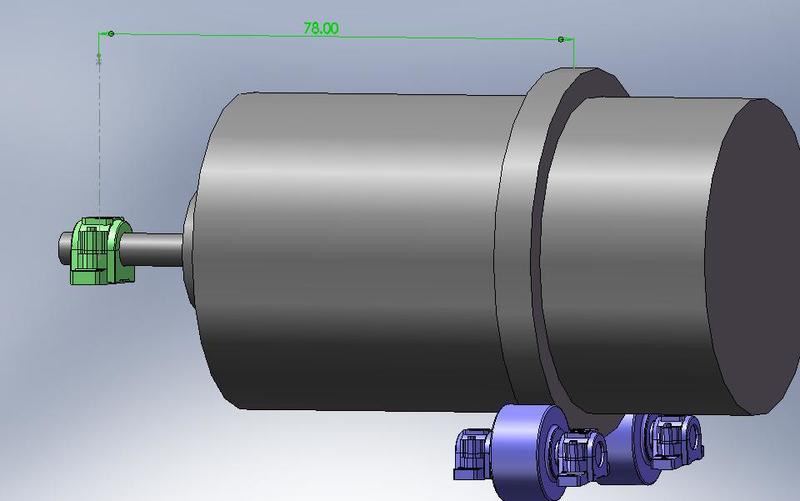

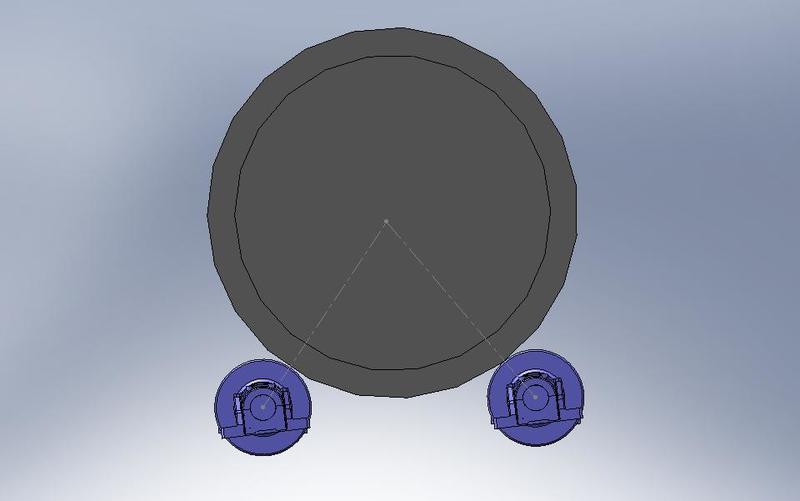

A 49" dia. steel tube (shell) with a 6" x 57.5" dia. steel ring (Tire) welded to the tube rotates horizontally at ~ 27 RPM. Inside of the shell are 42 - 2.5"dia x 6' long solid steel rods. It is held at one end by a 5" dia. bearing mounted shaft, at the other end the Tire sits on 2 bearing mounted 14" dia. rollers. The shaft support and the support rollers are 78" appart(from center of bearing to center of roller). The total wieght of this unit is 10,000lbs. The support rollers sit at 36deg from vertical or 72deg from each other. Is the force required to rotate the entire unit increased or decreased if the rollers are moved closer together so they were say 60deg apart? I have attached a quick sketch for clarity.

I hope I didn't miss something. Any help would be really great guys...Thanks in advance.

I hope I didn't miss something. Any help would be really great guys...Thanks in advance.