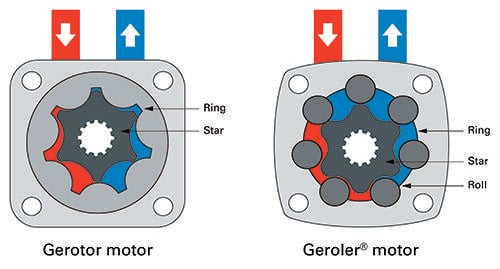

To design a custom Geroler motor, calculating torque requires understanding the areas opposing input and output pressures, as well as the crank radius. The torque formula involves the differential fluid pressure and the face area of the gear teeth. Using a compressible fluid like air instead of a liquid may affect leakage but not the fundamental calculations. The discussion highlights the complexity of creating a Geroler motor, suggesting that a traditional gear motor or Gerotor might be simpler alternatives. The design considerations also include the rotor's movement and the implications for fluid direction valves.