- #1

S_Noakes

- 23

- 1

- TL;DR Summary

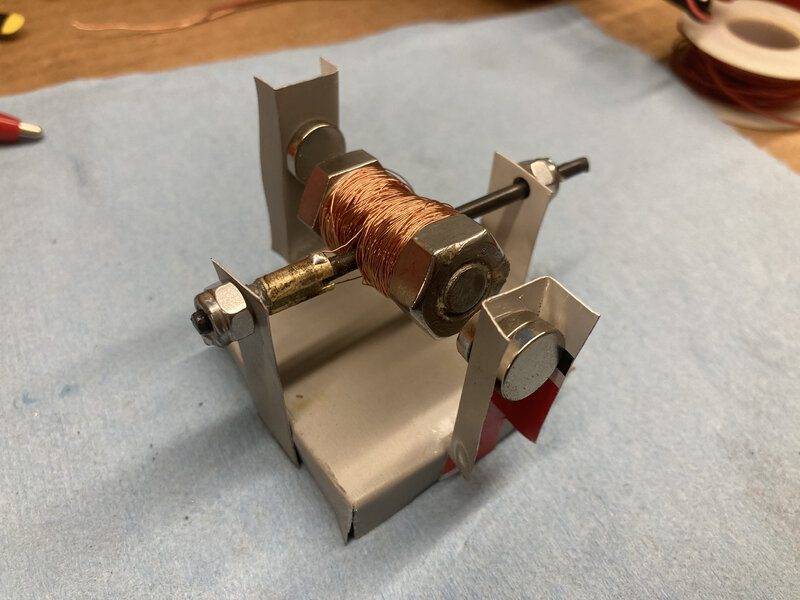

- For school, I am trying to make an electric motor. When I try to apply power across the commutator however, it will either twitch a little bit or do nothing at all.

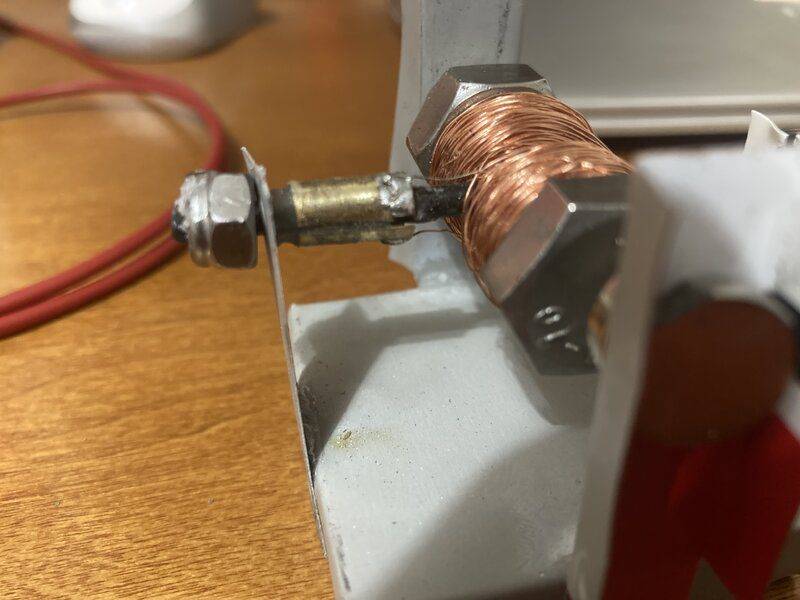

Here are the details. I started with a nut and bolt, and drilled a hole down the center of it. I inverted and glued into place a carbon fiber rod in the hole. I glued a bit on the end of the bolt. I wrapped magnet wire around the bolt on each side of the rod 400 times. I made a commutator using brass, and soldered one end of the wire to each side. The separation in the commutator is lined up the the bolt head and nut.

For magnets, I am using two small (but strong) magnets per side.

For power, I am using a 9-volt battery with copper wires connected to it. I’m touching the copper wires against the commutator 180 degrees apart.

The structure is made out of aluminum, if that matters.

What am I doing wrong? Am I missing anything obvious?

let me know if you want more info or pictures.

For magnets, I am using two small (but strong) magnets per side.

For power, I am using a 9-volt battery with copper wires connected to it. I’m touching the copper wires against the commutator 180 degrees apart.

The structure is made out of aluminum, if that matters.

What am I doing wrong? Am I missing anything obvious?

let me know if you want more info or pictures.