BrockLee

- 30

- 0

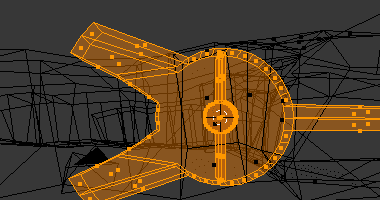

I have considered myself versed on a topic as broad as hydrolic and recently came to doubt myself on a simple idea of what it takes to actuate a hydrolic flow between a junction of two piston's, so taking in mind the simple shape in the image Could this be stopped once the flow is pushing only slightly into an expanding cylinder and what kind of current flow are we talking about, I have just read a literal ton of information on the inductance coupling and have the design for an inductive(single wire) motor control array(I'd be happy to share).