Dean Winchester

- 1

- 0

Hello,

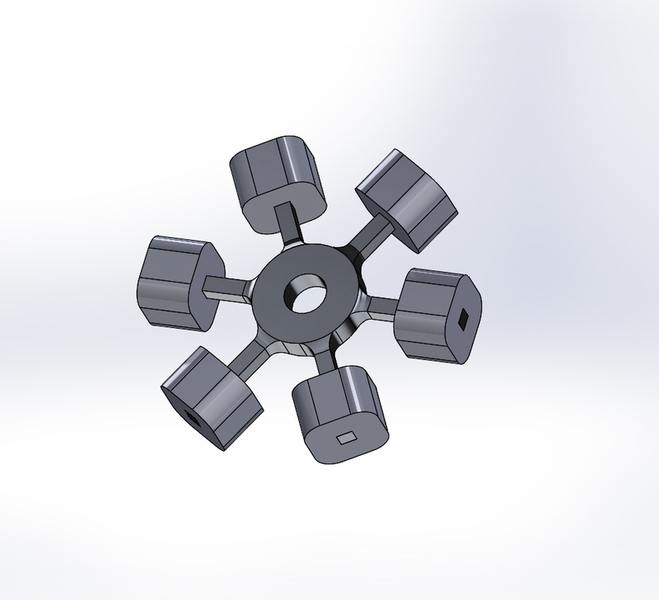

I have to design a high inertia flywheel for energy storage. The flywheel must be something like in the drawing I attached. The question is: how can I calculate the Inertia and the stored kinetic energy in this type of flywheel?

Can I consider it like a classic "Rim , hub and spokes" flywheel, thus considering it like if there was a continuous rim, and use the classic formulas found in literature, such as I_rim=m*R_m^2 (where R_m is the mean radius) for the inertia of the rim and E=1/2*I_r*w^2 for the kinetic energy stored?

Thanks a lot for your help!

I have to design a high inertia flywheel for energy storage. The flywheel must be something like in the drawing I attached. The question is: how can I calculate the Inertia and the stored kinetic energy in this type of flywheel?

Can I consider it like a classic "Rim , hub and spokes" flywheel, thus considering it like if there was a continuous rim, and use the classic formulas found in literature, such as I_rim=m*R_m^2 (where R_m is the mean radius) for the inertia of the rim and E=1/2*I_r*w^2 for the kinetic energy stored?

Thanks a lot for your help!