cognosco123

- 1

- 0

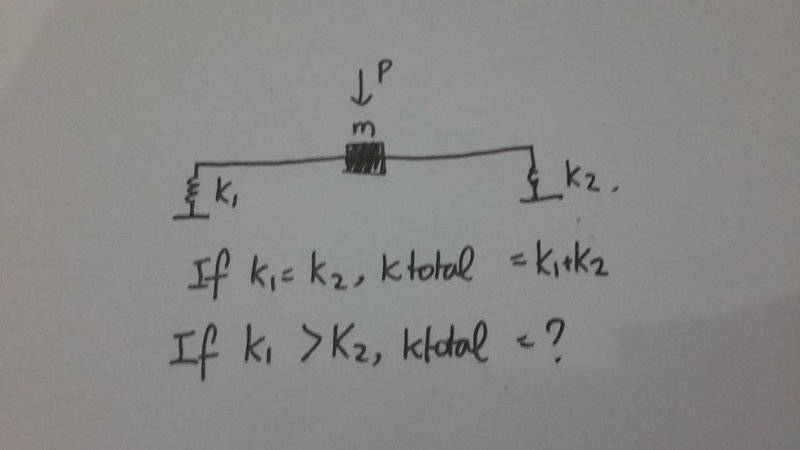

The problem is attached.

I'll disagree on this. The parallel springs formula assumes that both springs displace the same. Here, however, the springs will displace differently to maintain equilibrium. Therefore, a unique formula needs to be derived.Daniel Sadlier said:The equivalent spring constant Ktot = k1 + k2 no matter the values of k1 or k2.