SUMMARY

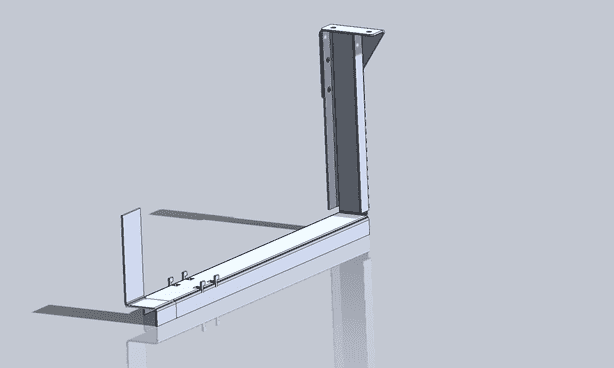

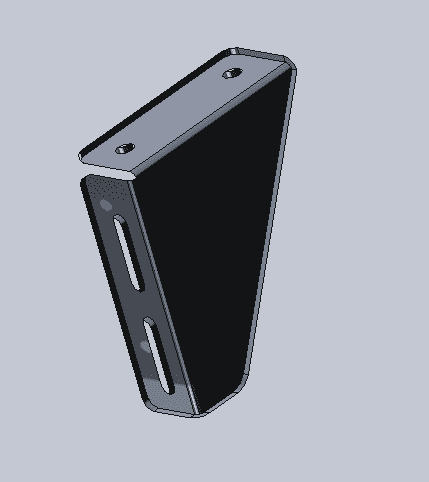

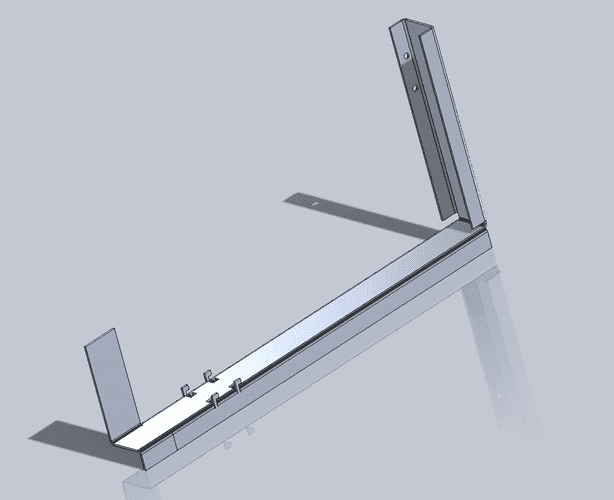

The discussion focuses on increasing the stiffness of a tool designed for precise positioning of a component. The tool consists of a main frame connected via nuts and bolts and features four teeth-like structures. Participants suggest using tubular materials instead of sheet metal or aluminum to enhance stiffness, while also emphasizing the importance of understanding load distribution and support mechanisms. The cost constraint for the project is set at under 50 euros.

PREREQUISITES

- Understanding of structural engineering principles

- Familiarity with materials such as sheet metal and aluminum

- Knowledge of load distribution and support mechanisms in mechanical design

- Basic concepts of manufacturing techniques

NEXT STEPS

- Research the benefits of using tubular structures in mechanical design

- Explore techniques for analyzing load distribution in structural components

- Investigate different manufacturing techniques suitable for aluminum and sheet metal

- Learn about stiffness optimization methods in mechanical engineering

USEFUL FOR

Mechanical engineers, product designers, and anyone involved in the design and optimization of structural components for precise positioning applications.