jendrix

- 120

- 4

Hello,

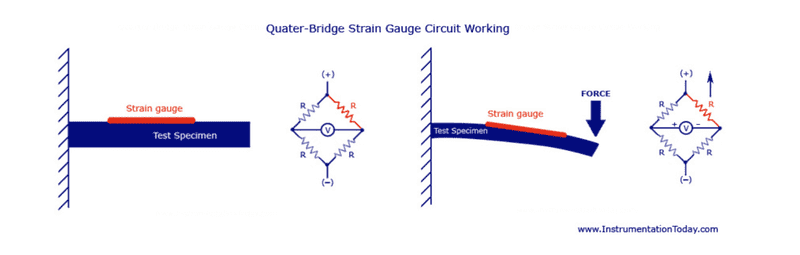

I am working on a project for an EE class and am brushing back up on the basics of strain and stress. My question was to do with how strain works in a material and if it is constant throughout. Say for example you had a setup like this

The change in resistance the strain gauge measures can be used to calculate the strain. Is this the same as the strain in the entire test specimen? So you can measure the strain at one position and this can be used to find the strain in the entire material?

If so is there an advantage to having a longer strain gauge?Thanks

I am working on a project for an EE class and am brushing back up on the basics of strain and stress. My question was to do with how strain works in a material and if it is constant throughout. Say for example you had a setup like this

The change in resistance the strain gauge measures can be used to calculate the strain. Is this the same as the strain in the entire test specimen? So you can measure the strain at one position and this can be used to find the strain in the entire material?

If so is there an advantage to having a longer strain gauge?Thanks