JustinLiang

- 79

- 0

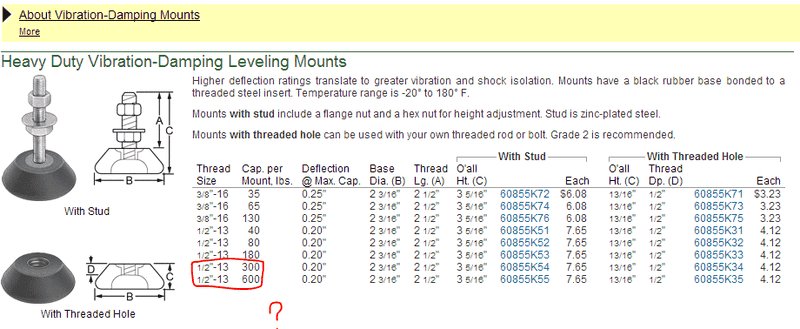

I need to build a platform (10 in off the ground) that can hold a fan, air damper and silencer which is in total around 300 lbs of weight. I was looking at these leveling mounts that I could use for the table feet:

I noticed that there is one that says 300 lbs capacity per mount and another one says 600 lbs capacity per mount. They are the same price so why would anyone want to purchase the 300 lb one?

Also, I just want to make sure... You can adjust these right? In case you want to make your table slightly higher?

Cheers

I noticed that there is one that says 300 lbs capacity per mount and another one says 600 lbs capacity per mount. They are the same price so why would anyone want to purchase the 300 lb one?

Also, I just want to make sure... You can adjust these right? In case you want to make your table slightly higher?

Cheers