- #1

adamkhalid02

- 2

- 0

Post moved from the technical forums to the Schoolwork forums

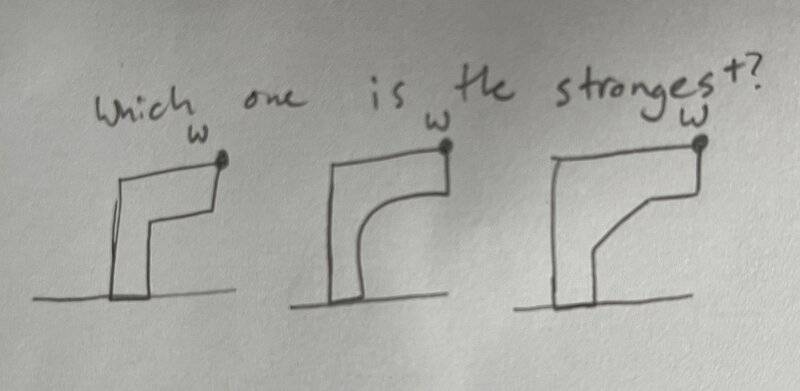

Summary: Each angle has a different type of corner, rectangular, circular, and triangular. Which one is the strongest?

All three angles are mounted in the ground and made of the same material. The same force ‘w’ towards the ground is acting on all angles, which one is the strongest?

Please explain why it is the strongest, I believe it is the circular one but can’t give a reason other than it has the most surface area to support the ‘w’.

All three angles are mounted in the ground and made of the same material. The same force ‘w’ towards the ground is acting on all angles, which one is the strongest?

Please explain why it is the strongest, I believe it is the circular one but can’t give a reason other than it has the most surface area to support the ‘w’.