Phi_lip

- 12

- 0

- TL;DR Summary

- I am planning to make a gong stand, using tube clamps and aluminium tubing, but I am unsure whether the tubing will be strong enough.

Hello everybody,

I am planning to make a gong stand using tube clamps and aluminium tubing, but I am unsure whether the tubing will be strong enough. I like the idea of using aluminium, to aid with portability of the stand. As the stand will be used to play the gong itself, which will move back and forth slightly and resonate, I imagine this is quite a difficult calculation to carry out. As the gong cost over £2000, I really do not want to drop this beautiful and expensive instrument. So thought I would ask for some advice.

The gong is 38" in diameter and weighs 15kgs.

The aluminium tubing I had in mind has an external diameter of 33mm and an internal wall of 3mm. It is an aluminium alloy (6082).

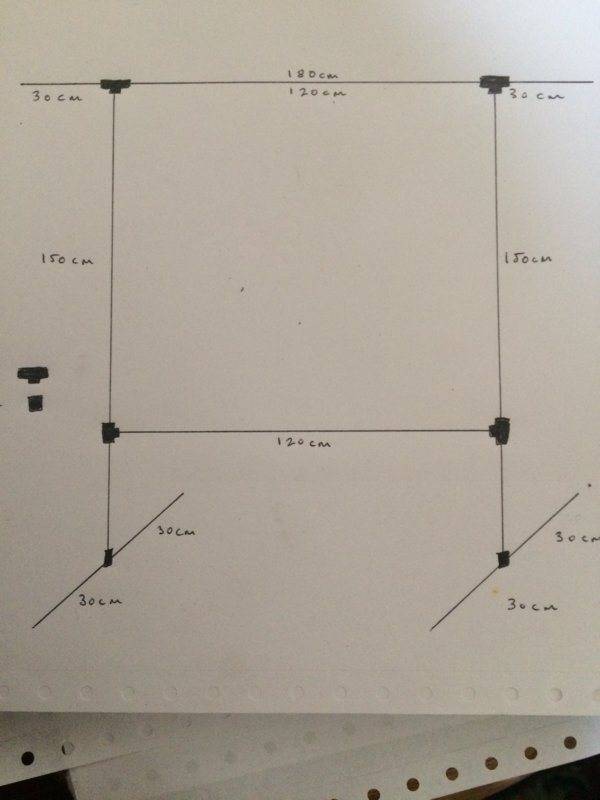

This is a rough plan for the stand...

Apologies if my writing is a little tiny and unclear. The top bar is 180cm, it overhangs 30cm on each side. So, the internal width is 120cm, height is 150cm, feet are 60cm. I will be using long tee tube clamps to fit it together. The clamps and tube are designed to be used for hand railing systems.

I could use aluminium with a thicker diameter and wall. I could also use steel. But, as the gong is already 15kgs, I would like to keep the weight down on the stand for easier transportation.

If anybody has any advice, it would be really helpful,

Philip

I am planning to make a gong stand using tube clamps and aluminium tubing, but I am unsure whether the tubing will be strong enough. I like the idea of using aluminium, to aid with portability of the stand. As the stand will be used to play the gong itself, which will move back and forth slightly and resonate, I imagine this is quite a difficult calculation to carry out. As the gong cost over £2000, I really do not want to drop this beautiful and expensive instrument. So thought I would ask for some advice.

The gong is 38" in diameter and weighs 15kgs.

The aluminium tubing I had in mind has an external diameter of 33mm and an internal wall of 3mm. It is an aluminium alloy (6082).

This is a rough plan for the stand...

Apologies if my writing is a little tiny and unclear. The top bar is 180cm, it overhangs 30cm on each side. So, the internal width is 120cm, height is 150cm, feet are 60cm. I will be using long tee tube clamps to fit it together. The clamps and tube are designed to be used for hand railing systems.

I could use aluminium with a thicker diameter and wall. I could also use steel. But, as the gong is already 15kgs, I would like to keep the weight down on the stand for easier transportation.

If anybody has any advice, it would be really helpful,

Philip