Will_SPHS

- 18

- 4

Poster has been reminded to post schoolwork in the Homework Help forums

I had posted a thread several months ago about a similar problem on the same project, but the parameters have changed and my question has slightly as well.

Background:

For a high school engineering class, each group must design and create a prototype of a solution to an environmental related problem. My group is looking to automate the process of turning compost, thereby speeding up the process.

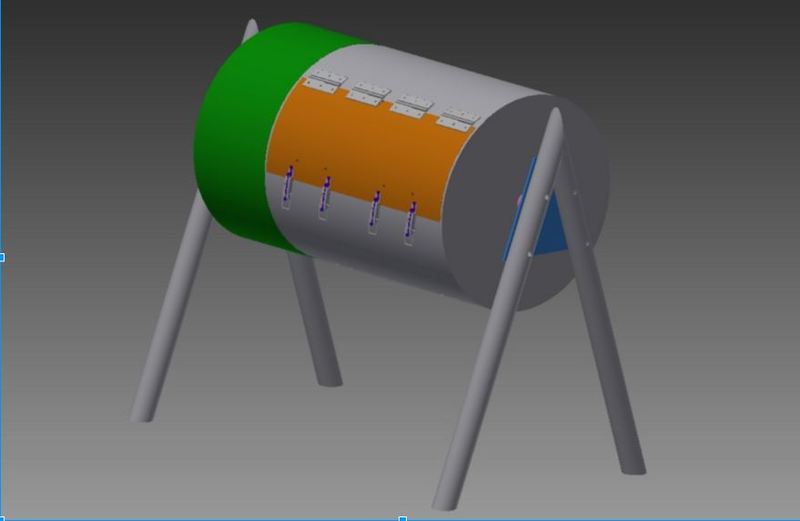

We designed a compost tumbler that consists of a drum (shown below as gray) and motor housing (shown below as green) around an axle mounted onto supports with ball bearings. The final design (not shown) has struts, uses less hinges, and is smaller, but the image gives a rough idea. The motor has room to be geared down to increase the torque if need be.

Calculations:

Drum Radius = 5.625"

Drum Height = 12.50"

Drum Volume = 0.704 ft3 = 5.27 gallons

Compost Weight (when full of compost at 76 lb per cubic foot) = 53.5 lb

Drum Weight = 15 lb

Torque (I was told to use Weight*Radius) = (53.5 lb + 15 lb)*.469 ft = 32.13 lb*ft

Moment of Inertia of Drum (I = 1/2*mr^2) = .5 * 23 kg * (0.02045 m^2) = 0.235 kg*m^2

Power (P = Tω) = 32.13 lb*ft * 0.52 rad/s = 16.71 lbft/s = 22.66 Watts

For the power calculation, I used 5 rpm (.52 rad/s), but I suppose this speed could be reduced as the turning speed isn't something that needs to be precise.

Questions:

How would I factor in the moment of inertia of the drum into the motor selection, and would the frictional force be large enough where I would have to take it into consideration, considering I am using bearings?

How would I decide what motor I would need to use? I suppose with a safety factor, the moment of inertia, and friction (not calculated), I could used a motor around 50 Watts. Does that seem correct? I feel like I am missing something, because motors (ex: http://www.mcmaster.com/#6409k15/=11jetjs) with very little horsepower (in this case, 0.0077 HP / 5.74 Watts) and RPM (12) seem to cost a lot of money (>$50 with this motor example). I could gear down the motor regardless to decrease the RPM and increase the torque.

Thanks for any help you can give!

Background:

For a high school engineering class, each group must design and create a prototype of a solution to an environmental related problem. My group is looking to automate the process of turning compost, thereby speeding up the process.

We designed a compost tumbler that consists of a drum (shown below as gray) and motor housing (shown below as green) around an axle mounted onto supports with ball bearings. The final design (not shown) has struts, uses less hinges, and is smaller, but the image gives a rough idea. The motor has room to be geared down to increase the torque if need be.

Calculations:

Drum Radius = 5.625"

Drum Height = 12.50"

Drum Volume = 0.704 ft3 = 5.27 gallons

Compost Weight (when full of compost at 76 lb per cubic foot) = 53.5 lb

Drum Weight = 15 lb

Torque (I was told to use Weight*Radius) = (53.5 lb + 15 lb)*.469 ft = 32.13 lb*ft

Moment of Inertia of Drum (I = 1/2*mr^2) = .5 * 23 kg * (0.02045 m^2) = 0.235 kg*m^2

Power (P = Tω) = 32.13 lb*ft * 0.52 rad/s = 16.71 lbft/s = 22.66 Watts

For the power calculation, I used 5 rpm (.52 rad/s), but I suppose this speed could be reduced as the turning speed isn't something that needs to be precise.

Questions:

How would I factor in the moment of inertia of the drum into the motor selection, and would the frictional force be large enough where I would have to take it into consideration, considering I am using bearings?

How would I decide what motor I would need to use? I suppose with a safety factor, the moment of inertia, and friction (not calculated), I could used a motor around 50 Watts. Does that seem correct? I feel like I am missing something, because motors (ex: http://www.mcmaster.com/#6409k15/=11jetjs) with very little horsepower (in this case, 0.0077 HP / 5.74 Watts) and RPM (12) seem to cost a lot of money (>$50 with this motor example). I could gear down the motor regardless to decrease the RPM and increase the torque.

Thanks for any help you can give!