Darcy30

- 1

- 1

Hallo. Since I'm new in this field, I hope someone can help me.

I have a laminar, steady state, incompressible flow in a channel (a fully developed).

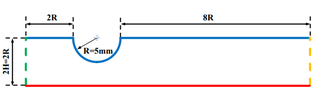

Geometry of the channel is on the photo.

How should I calculate the drop of static pressure across the channel?

Since I have Re, I did calculate a inlet velocity, but now I'm stuck.

Thanks

I have a laminar, steady state, incompressible flow in a channel (a fully developed).

Geometry of the channel is on the photo.

How should I calculate the drop of static pressure across the channel?

Since I have Re, I did calculate a inlet velocity, but now I'm stuck.

Thanks