- #1

Howlin

- 55

- 0

Hi all

I have the following question that I require help with.

1. Homework Statement

A supply fan must deliver 2.5m3s of air against a system pressure of 500 Pa.The selected fir this has a performance characteristic as listed below when running at a speed of 1800 revs/min.

i) Plot the system characteristic and determine the actual operating point when the fan is connected to the system.

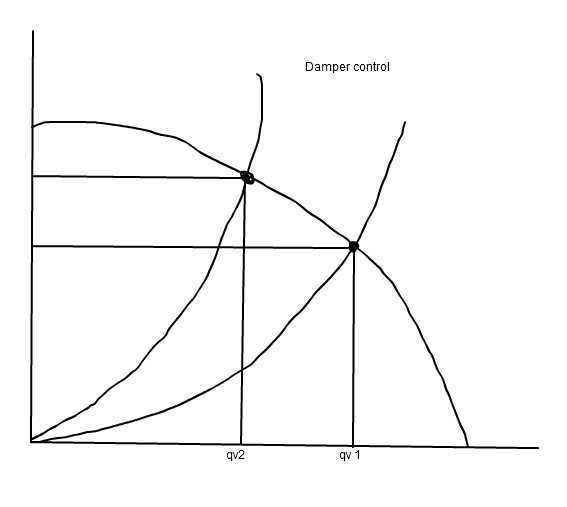

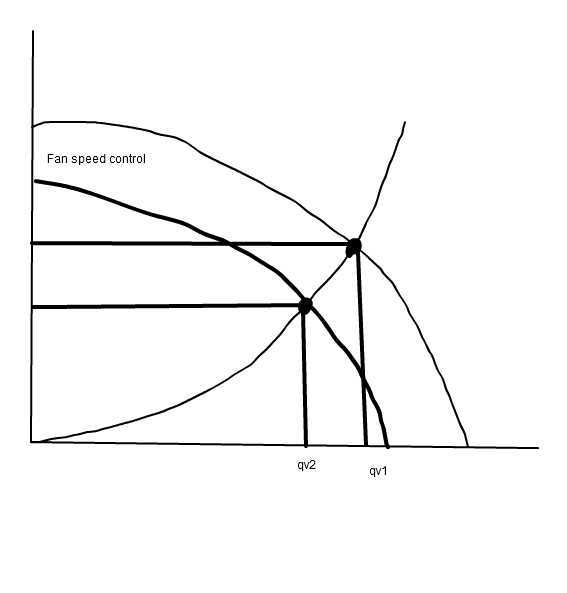

ii) Show using simple sketches the difference between using damper control and speed control to obtain the design flow rates of 2.5m3/s.

iii)Calculate the speed the fan should run at to deliver the design flow rate.

iv) Calculate the kW savings that can be made by using speed controls instead of damper control

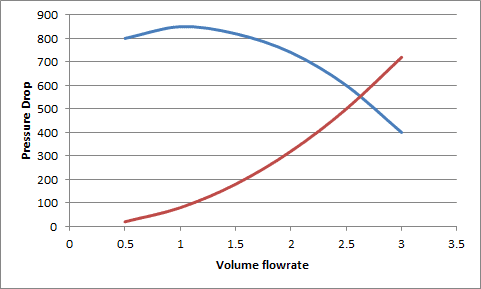

Volume Flow Rate (m3/s) ......0.5 1 1.5 2 2.5 3

Pressure drop (Pa) .......800 850 820 740 600 400

Power(kW) ..........0.53 1.1 1.54 1.8 1.88 1.74

2. Homework Equations

Given none but equations I have used:

ΔP = c* qv2

i)

c = ΔP/qv2

c = 500/2.52

c = 80

ΔP1 = 80*.52 = 20

ΔP1 = 80*.1.02 =80

ΔP1 = 80*1.52 = 180

ΔP1 = 80*2.02 = 320

ΔP1 = 80*2.52 = 500

ΔP1 = 80*3.02 = 720

I graphed this data and got the following graph:

The lines intersect at approximately 2.6m3/s and 528 kPaI do not know how to work out ii)

but I think they are the following but I don't understand it

iii)

The equation to work out the speed of the fan below but I am unsure which values go in where.

N1 / N2 = F1/F2iv)

The equation to work out the kW savings

W1/ W2 = N1/N2

and work is

W = qv *ΔPa/η

I am unsure how to work this out.

Can anyone help me by nudging me in the right direction? Thank you in advance

Regards,

Stephen

I have the following question that I require help with.

1. Homework Statement

A supply fan must deliver 2.5m3s of air against a system pressure of 500 Pa.The selected fir this has a performance characteristic as listed below when running at a speed of 1800 revs/min.

i) Plot the system characteristic and determine the actual operating point when the fan is connected to the system.

ii) Show using simple sketches the difference between using damper control and speed control to obtain the design flow rates of 2.5m3/s.

iii)Calculate the speed the fan should run at to deliver the design flow rate.

iv) Calculate the kW savings that can be made by using speed controls instead of damper control

Volume Flow Rate (m3/s) ......0.5 1 1.5 2 2.5 3

Pressure drop (Pa) .......800 850 820 740 600 400

Power(kW) ..........0.53 1.1 1.54 1.8 1.88 1.74

2. Homework Equations

Given none but equations I have used:

ΔP = c* qv2

The Attempt at a Solution

i)

c = ΔP/qv2

c = 500/2.52

c = 80

ΔP1 = 80*.52 = 20

ΔP1 = 80*.1.02 =80

ΔP1 = 80*1.52 = 180

ΔP1 = 80*2.02 = 320

ΔP1 = 80*2.52 = 500

ΔP1 = 80*3.02 = 720

I graphed this data and got the following graph:

The lines intersect at approximately 2.6m3/s and 528 kPaI do not know how to work out ii)

but I think they are the following but I don't understand it

iii)

The equation to work out the speed of the fan below but I am unsure which values go in where.

N1 / N2 = F1/F2iv)

The equation to work out the kW savings

W1/ W2 = N1/N2

and work is

W = qv *ΔPa/η

I am unsure how to work this out.

Can anyone help me by nudging me in the right direction? Thank you in advance

Regards,

Stephen