- #1,576

- 2,340

- 354

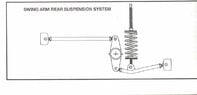

We found out the top link mounting point on the rear end was same setting as from the Port City factory. We are running 58% left side weight so the distance from right rear tire centerline to tip link mount was off 6". since we can only use solid links , no springer top link or spring trailing arms, the mount location is vital to good tire hook up. As found distance from rt rear CL was 32" on 66" rear track width. So 58% left side weight means the mount point is 66 x .58 = 38.25" and changing it means both rear tires are loading the same.

Attachments

Last edited: