Discussion Overview

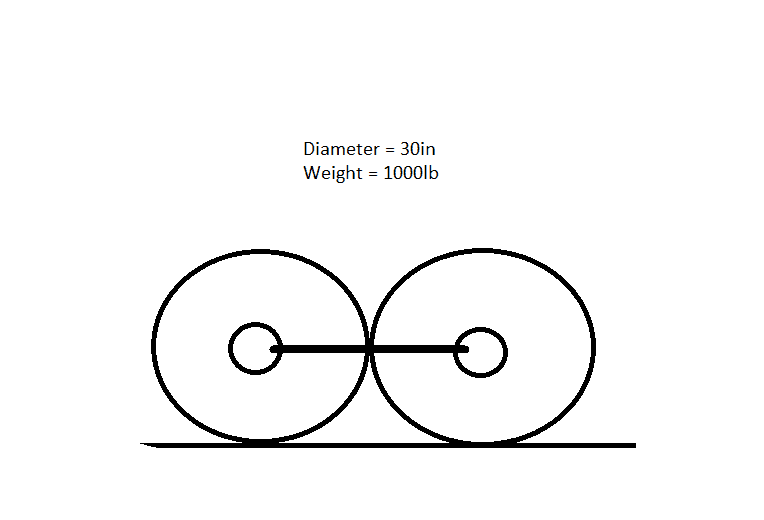

The discussion focuses on determining the strength required for a strap to securely connect two large rolls of plastic sheets, each weighing 1000 lbs, for shipping purposes. Participants explore various scenarios and factors that could affect the strap's strength, including angles of tension and the potential for movement during transport.

Discussion Character

- Exploratory

- Technical explanation

- Debate/contested

- Experimental/applied

Main Points Raised

- Some participants suggest that the application context is crucial, questioning whether the rolls are stationary or subject to movement during transport.

- One participant proposes that if the rolls are simply sitting, minimal strength is needed, while another emphasizes the need for a strap capable of withstanding forces due to potential angles of tension.

- A participant outlines worst-case scenarios where one roll could hang at an angle, estimating forces on the strap at 707 lbs for a 45-degree angle and 1000 lbs for a 60-degree angle.

- Another participant raises the importance of material properties and friction, suggesting that the coefficient of friction between the rolls could affect the required strap strength.

- Some participants inquire about the packaging and handling of the rolls, as well as the need for joining them instead of crating them together.

- There is a suggestion to consider the impact of shipping conditions, such as g-forces during air transport, on the strap's strength requirements.

- One participant introduces the idea of strapping three rolls together in a triangular formation to enhance stability and reduce reliance on surface friction.

Areas of Agreement / Disagreement

Participants express various viewpoints on the factors influencing strap strength, with no consensus reached on a definitive solution or approach. The discussion remains open-ended with multiple competing ideas and scenarios presented.

Contextual Notes

Participants note that additional information about the specific application, materials, and handling processes is necessary to refine their assessments. The discussion highlights the complexity of the problem, including the interplay of forces and material properties.