gogogsr

- 9

- 0

Hey guys, how are you?

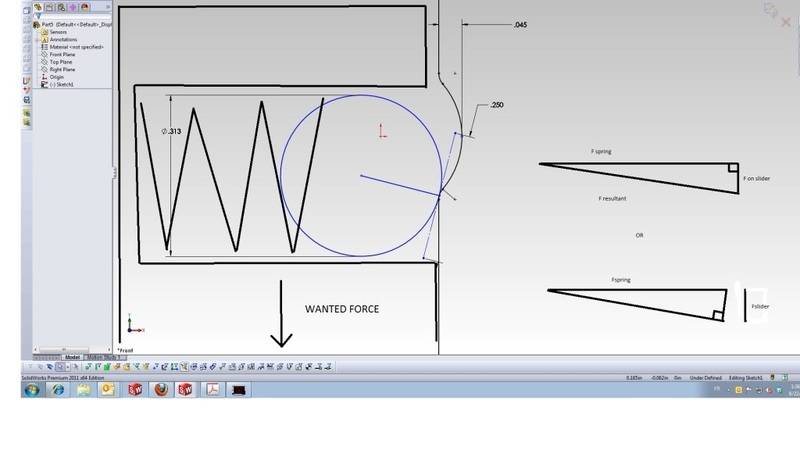

I feel so stupid right now, I'm having a hard time getting my mind straight, which of the two resultant force diagram on the right is right? Typically its a slider with a ball and spring that slides on a recess (cam type). I want to know the force required on the slider to make it slide, here is the diagram. Thanks guys

I feel so stupid right now, I'm having a hard time getting my mind straight, which of the two resultant force diagram on the right is right? Typically its a slider with a ball and spring that slides on a recess (cam type). I want to know the force required on the slider to make it slide, here is the diagram. Thanks guys