NewEngineer

- 21

- 2

What's happening Form,

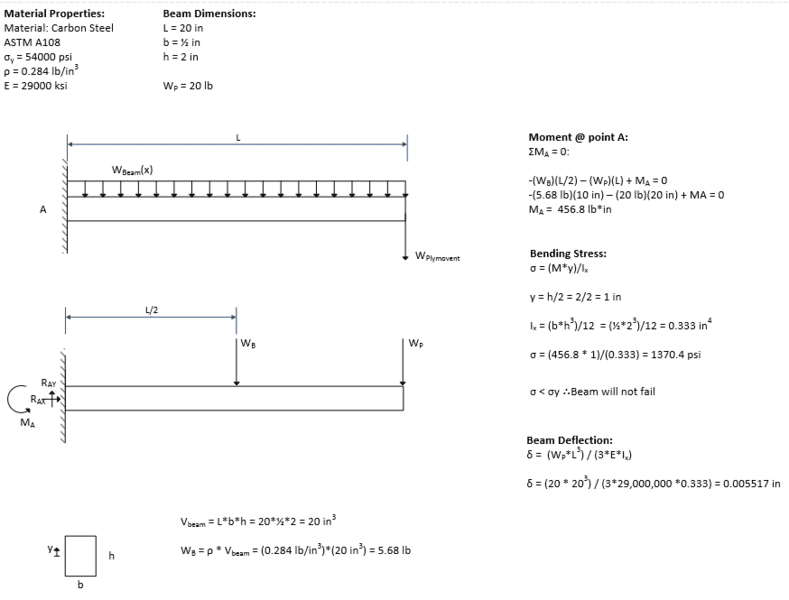

It's been a while since I've done a FBD, but I wanted to get someone's input here and tell me if my math/logic is correct. I want to install a cantilever steel beam with a 20 lb mass at the end of it. I'm using carbon steel ASTM A108 (cheapest steel on McMaster-carr). I plan on the cross section being 0.5" x 2". According to the math below, the beam should not fail correct? As long as the bending stress is lower than the yield stress we should be ok, correct? Is there something else I should take into consideration here?

Also, the mass on the end of the beam may be pull in direction coming out from the page. Would adding a truss feature help negate the stress in the beam, or is best option to use a thicker piece of material?

It's been a while since I've done a FBD, but I wanted to get someone's input here and tell me if my math/logic is correct. I want to install a cantilever steel beam with a 20 lb mass at the end of it. I'm using carbon steel ASTM A108 (cheapest steel on McMaster-carr). I plan on the cross section being 0.5" x 2". According to the math below, the beam should not fail correct? As long as the bending stress is lower than the yield stress we should be ok, correct? Is there something else I should take into consideration here?

Also, the mass on the end of the beam may be pull in direction coming out from the page. Would adding a truss feature help negate the stress in the beam, or is best option to use a thicker piece of material?