Dell

- 555

- 0

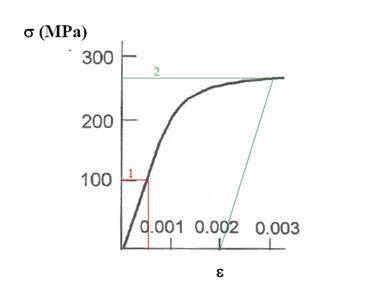

as depicted in the diagram below

the stress strain for an alloy with an average nucleus size of 100 micron

find

1)the modulus of elasticity for the alloy

2) the yielding stress

for 1) i assume that the red line is meant to be at 0.0005 therefore

E=dσ/dε=100e6/0.0005

E=200Gpa

for 2) i don't know what i can do, all that i do know is that the slant of the line from ε=0.002 to the point of σy is equal to 200Gpa (from the E i found before), but how can i use this to find the stress, i do not know the strain for σy, since i was given the nuclesu size i think i must somehow use that, but how??

the stress strain for an alloy with an average nucleus size of 100 micron

find

1)the modulus of elasticity for the alloy

2) the yielding stress

for 1) i assume that the red line is meant to be at 0.0005 therefore

E=dσ/dε=100e6/0.0005

E=200Gpa

for 2) i don't know what i can do, all that i do know is that the slant of the line from ε=0.002 to the point of σy is equal to 200Gpa (from the E i found before), but how can i use this to find the stress, i do not know the strain for σy, since i was given the nuclesu size i think i must somehow use that, but how??