AnotherParadox

- 35

- 3

Ok, so this is an undergraduate level question probably but consider this

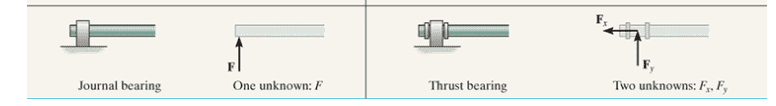

R. C. Hibbeler's Textbook on Mechanics of Materials says this about thrust bearings and smooth journal Bearings :

In other words, it says nothing about reaction moments. Now this chart has other 2D connection types that include a counter or reaction moment such as a fixed support that has 3 unknowns in 2D (M, Fx, Fy) or 3 reaction forces. So it's safe to say already that Hibbeler does not consider journal and thrust bearings to have reaction moments.

But to double check that he's saying this I looked at the first problem set

Now you are probably wondering how to solve this while consider the reaction moments at A and B, but before you strain yourself on that idea just take a look at a solution manual and you'll see it doesn't consider them at all. It leads to answers of 233 N for the resultant internal loading at point C and 433 N*m for the bending moment.

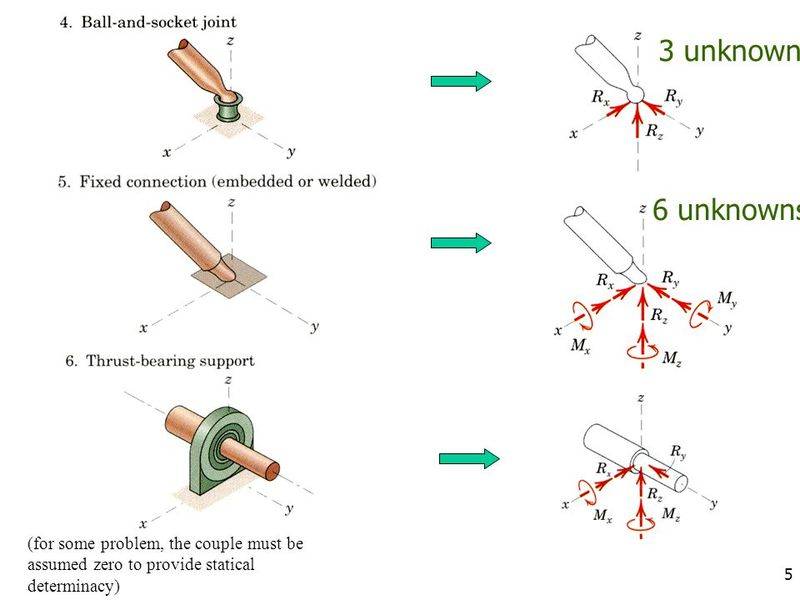

A quick search and general intuition would tell you there are probably reaction moments at both A and B or on both thrust bearings and smooth journal bearings.

The rod a is long cylinder in-closed by a 'bracket' with a cylindrical hole in it. If you slide a cylinder in a cylindrical hole it's only going to turn about its axis. Turning perpendicular isn't going to work thus a counter moment. As shown below (results for searching thrust bearing reaction forces)

And again

In most results you see a reaction moment in the X and Z axis, yet this is and my own intuition is inconsistent with Hibbeler's textbook.

Are there different types of bearings that do or don't have reaction moments in the X and Z axes? Is Hibbeler wrong, is my intuition and these searches wrong? Is everyone wrong? Are they both right? Is this simple a common different 'flavor' of material?

What am I missing here? This shouldn't be so difficult, at least not unless I'm missing something major.

R. C. Hibbeler's Textbook on Mechanics of Materials says this about thrust bearings and smooth journal Bearings :

In other words, it says nothing about reaction moments. Now this chart has other 2D connection types that include a counter or reaction moment such as a fixed support that has 3 unknowns in 2D (M, Fx, Fy) or 3 reaction forces. So it's safe to say already that Hibbeler does not consider journal and thrust bearings to have reaction moments.

But to double check that he's saying this I looked at the first problem set

Now you are probably wondering how to solve this while consider the reaction moments at A and B, but before you strain yourself on that idea just take a look at a solution manual and you'll see it doesn't consider them at all. It leads to answers of 233 N for the resultant internal loading at point C and 433 N*m for the bending moment.

A quick search and general intuition would tell you there are probably reaction moments at both A and B or on both thrust bearings and smooth journal bearings.

The rod a is long cylinder in-closed by a 'bracket' with a cylindrical hole in it. If you slide a cylinder in a cylindrical hole it's only going to turn about its axis. Turning perpendicular isn't going to work thus a counter moment. As shown below (results for searching thrust bearing reaction forces)

And again

In most results you see a reaction moment in the X and Z axis, yet this is and my own intuition is inconsistent with Hibbeler's textbook.

Are there different types of bearings that do or don't have reaction moments in the X and Z axes? Is Hibbeler wrong, is my intuition and these searches wrong? Is everyone wrong? Are they both right? Is this simple a common different 'flavor' of material?

What am I missing here? This shouldn't be so difficult, at least not unless I'm missing something major.

Last edited: