- #1

asoundha

- 6

- 0

Greetings all,

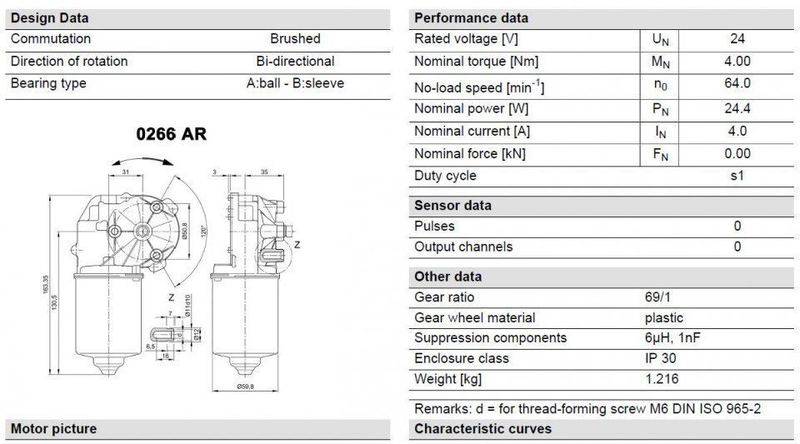

I am trying to build a sliding gate operator. I have this wiper motor which says, 24v dc, 64rpm, nominal torque- 4Nm.

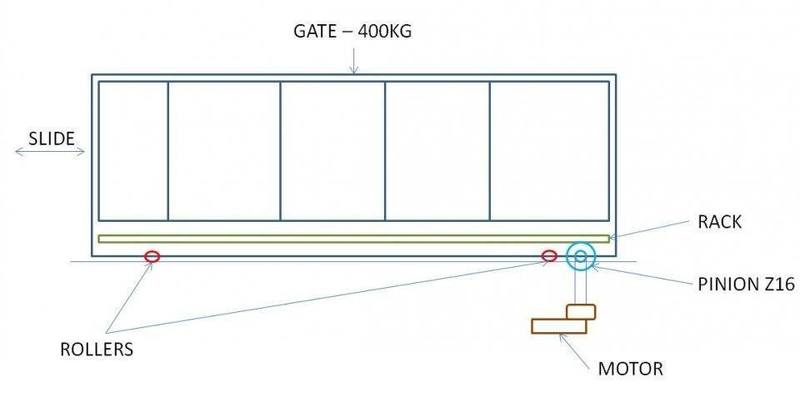

Max weight of gate to be 400kg, sliding on a steel rail (Not sure how to consider rolling resistance or Co-eff of friction) . Max pull force to be achieved by motor is 550N. Rack & Pinion is used to transmit force from motor to gate. velocity to be 9 cm/sec worst case.

Pinion = Z16

All i need to do is validate that the above motor is capable of pulling a 400kg gate.

I am trying to build a sliding gate operator. I have this wiper motor which says, 24v dc, 64rpm, nominal torque- 4Nm.

Max weight of gate to be 400kg, sliding on a steel rail (Not sure how to consider rolling resistance or Co-eff of friction) . Max pull force to be achieved by motor is 550N. Rack & Pinion is used to transmit force from motor to gate. velocity to be 9 cm/sec worst case.

Pinion = Z16

All i need to do is validate that the above motor is capable of pulling a 400kg gate.