Muthana Gubran

Trying to identify a method of improving angular repeat-ability and reliability of our measurement devices. The way this will be done, is by doing research and utilize an alternative form of measurement and detection.

This method will involves adding a sensor to the existing fixtures and future fixtures, that may help reproduce an outcome of unchanged conditions. When doing so an error can be mapped and compensated for.

Issue: Unknown “slip” or misalignment between sensor actual position and encoder.

Trying to improve the Testing Accuracy and repeat-ability.

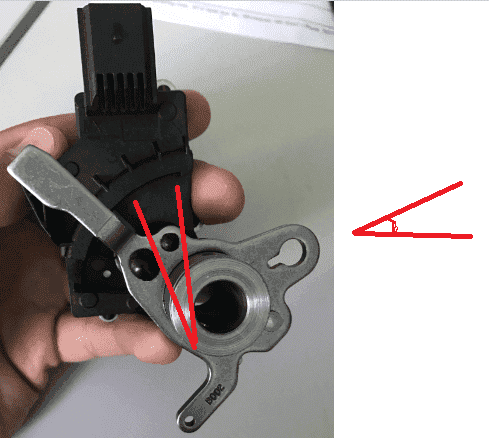

There is a fixture that holds everything in place.The component is connected to the shaft and the face of the fixture, and the shaft connected to the encoder.

I attached the picture of the component. Any idea what I should do ?

Note the metal on the component rotates to a certain degree, and has to meet in between a certain angle.

I wanted to connect a sensor outside of the fixture, that may map an angular position. Is there anything I need to know. I want to gain more knowledge on what technique I should use.

This method will involves adding a sensor to the existing fixtures and future fixtures, that may help reproduce an outcome of unchanged conditions. When doing so an error can be mapped and compensated for.

Issue: Unknown “slip” or misalignment between sensor actual position and encoder.

Trying to improve the Testing Accuracy and repeat-ability.

There is a fixture that holds everything in place.The component is connected to the shaft and the face of the fixture, and the shaft connected to the encoder.

I attached the picture of the component. Any idea what I should do ?

Note the metal on the component rotates to a certain degree, and has to meet in between a certain angle.

I wanted to connect a sensor outside of the fixture, that may map an angular position. Is there anything I need to know. I want to gain more knowledge on what technique I should use.