addibigg

- 1

- 0

- TL;DR Summary

- Drain channel minimal cross-section

Hi there!

I'm looking for an approx. minimal size for a drain channel where condensation water can go through. Can anyone have some advice?

No increased pressure for the water, just the normal atmospheric pressure. Water condensing and just have to be able to get out.

The amount of water is small, let's say 50-100ml/hours.

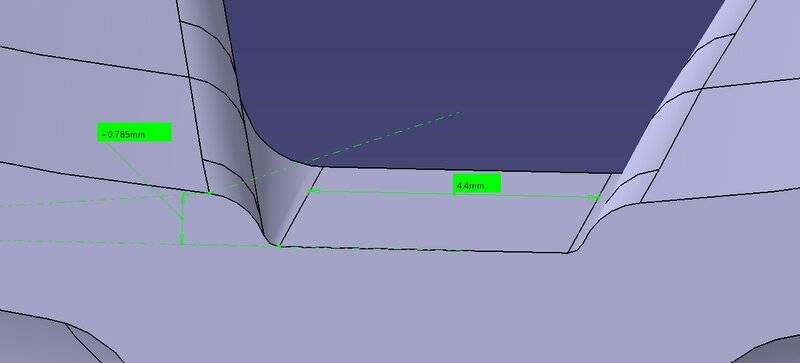

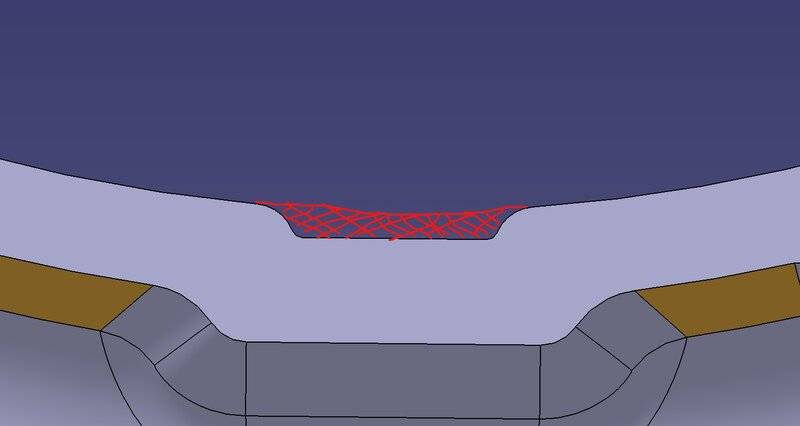

Attached the first draft of the channel. Smallest cross-section:

Any standards (if exists) could be good too, so I can refer to it.

Thanks!

Regards,

Ádám

I'm looking for an approx. minimal size for a drain channel where condensation water can go through. Can anyone have some advice?

No increased pressure for the water, just the normal atmospheric pressure. Water condensing and just have to be able to get out.

The amount of water is small, let's say 50-100ml/hours.

Attached the first draft of the channel. Smallest cross-section:

Any standards (if exists) could be good too, so I can refer to it.

Thanks!

Regards,

Ádám