fog37

- 1,566

- 108

- TL;DR

- How to apply Bernoulli eqn to a real life scenario

Hello,

I think I understand how Bernoulli equations works but I am clearly uncertain on some aspects of its application. For example, let's look at the figure below:

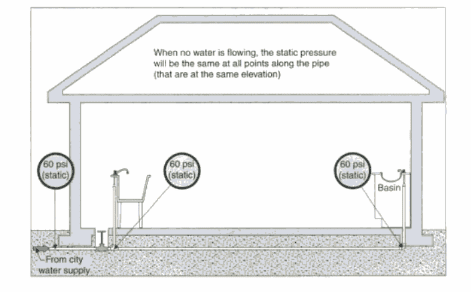

1) The static pressure is ##60## ##psi## from the city water supply. There is not flow (tap closed) so the pressure at the either basin is also ##60psi## regardless of the the pipe length, diameter, internal friction, number of bends/turns. We can measure that pressure, when the water is not moving, using pressure gauges.

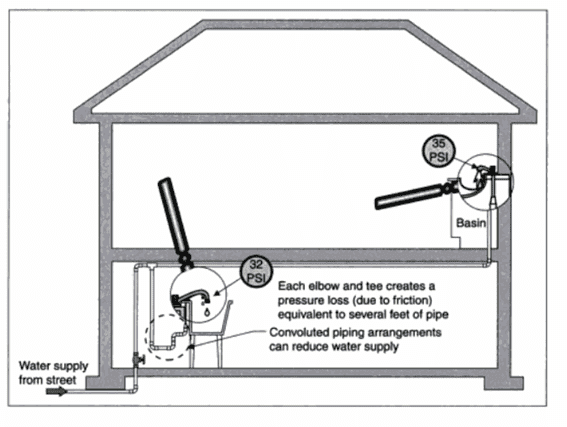

2) Now we open the tap at one of the basis and water starts flowing. The pressure from the city water supply is still ##60## ##psi##. But the pressure along the pipe decreases due to a) friction, b) pipe bends/curves, c) elevation changes, so the pressure at either basin\ is ##p<60## ##psi##.

Questions

1) Shouldn't the water pressure ##p## be equal to atmospheric pressure at the tap of each basis where the water exists? Why not? Why is the pressure ##35## ##psi## at the tap of the top basin and is not equal to atmospheric pressure?

2) In the ideal case (no friction, no bends, no elevation changes), the pressure at the basins would also be equal to ##60## ##psi## even when the water flows (not just in the static case) and the tap is open, correct? There would be a sharp pressure discontinuity at the tap, with pressure going from #60## ##psi## to atmospheric pressure...

3) The flow rate (gallons/minute) is determined by pipe's cross-sectional area ##A## and speed ##v## at the tap (I think).

What is the role of tap pressure (downstream)? The larger the tap pressure the larger the flow rate? Or what matters is only the water pressure upstream at the water supply from the street (bottom left)?

For example, let's assume the same pipe diameter, length, friction, and same pressure upstream (##60## ##psi##) but a different pressure downstream at the tap. How does that affect the flow rate? Is the flow rate lower? Why?

Thank you!Thank you!

I think I understand how Bernoulli equations works but I am clearly uncertain on some aspects of its application. For example, let's look at the figure below:

1) The static pressure is ##60## ##psi## from the city water supply. There is not flow (tap closed) so the pressure at the either basin is also ##60psi## regardless of the the pipe length, diameter, internal friction, number of bends/turns. We can measure that pressure, when the water is not moving, using pressure gauges.

2) Now we open the tap at one of the basis and water starts flowing. The pressure from the city water supply is still ##60## ##psi##. But the pressure along the pipe decreases due to a) friction, b) pipe bends/curves, c) elevation changes, so the pressure at either basin\ is ##p<60## ##psi##.

Questions

1) Shouldn't the water pressure ##p## be equal to atmospheric pressure at the tap of each basis where the water exists? Why not? Why is the pressure ##35## ##psi## at the tap of the top basin and is not equal to atmospheric pressure?

2) In the ideal case (no friction, no bends, no elevation changes), the pressure at the basins would also be equal to ##60## ##psi## even when the water flows (not just in the static case) and the tap is open, correct? There would be a sharp pressure discontinuity at the tap, with pressure going from #60## ##psi## to atmospheric pressure...

3) The flow rate (gallons/minute) is determined by pipe's cross-sectional area ##A## and speed ##v## at the tap (I think).

What is the role of tap pressure (downstream)? The larger the tap pressure the larger the flow rate? Or what matters is only the water pressure upstream at the water supply from the street (bottom left)?

For example, let's assume the same pipe diameter, length, friction, and same pressure upstream (##60## ##psi##) but a different pressure downstream at the tap. How does that affect the flow rate? Is the flow rate lower? Why?

Thank you!Thank you!