FEAnalyst said:

I’m asking for additional explanation regarding your solution.

There is insufficient information to be certain of any precise numerical result.

We do not need to chase the OP away with a shower of questions.

We just need an approximate answer, ignoring wind forces.

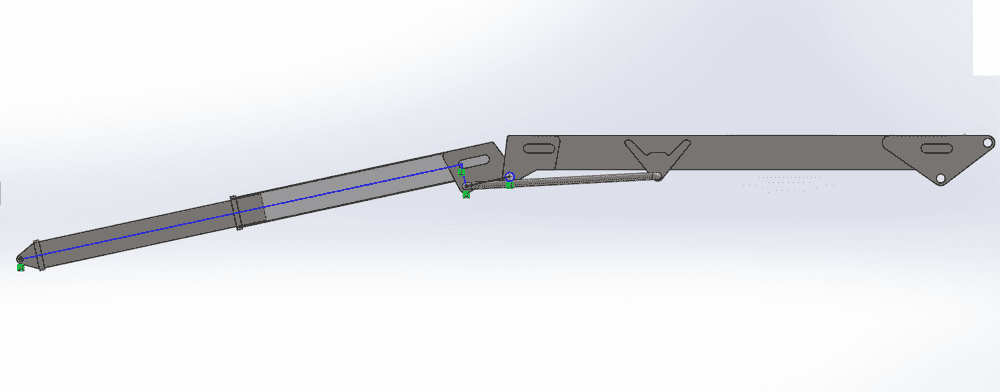

A crane boom and jib can be manipulated into many orientations. This is a student's concept, not an optimised design. It is shown in what is a "close to worst case position”. The following four steps appeared fundamental to my first approximation.

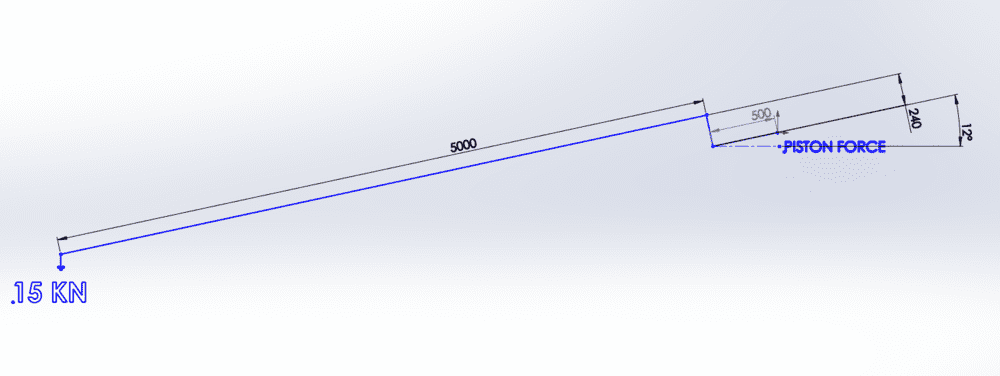

1. The 240 mm sidestep in the jib is irrelevant in the first analysis, so I ignore it.

2. The load is 150 N, so the crane can be a very light weight structure, probably a composite tube.

3. The jib is a lever that is 5500 mm long, with hydraulic force applied at 500 mm. That provides the ( 5500 / 500 ) term.

4. The hydraulic cylinder applies a force between the boom and jib. Model the elbow as two links with a 180° sweep. Then at 90° (between jib and cylinder) the cylinder will apply force directly with factor of 1.0; At 0° and 180° the points of attachment will be in line so the force will be infinite. The appropriate first order approximation is therefore the reciprocal of the sine function.

That explains the three terms of my approximation. F = 0.15 kN * ( 5500 / 500 ) / Sin( 12° ).