- #1

HomeExperiement

- 55

- 5

Hi!

I have question about high frequency transformers inside switch mode power supplies (SMPS). Is it normal for them to become hot under no load or low load? For example if power supply is rated for 144A at 13.8V and I only pull from it 2A at 9.6V, it normal that transformer becomes about 50C just in about 10 minutes or should it stay at room temperature at that low load? The size of transformer is roughly 5x5x5 cm. Or does it mean that something is wrong with transformer? Also, when load is less than 1A transformer starts to make high pitch (around 10-12 kz I think, can't measure it) whistling noise - is this normal or is it sign of low quality cheap PWM controller? When I increase the load the noise fades out - or what it seems like it just goes outside of human hearing range.

I am asking about this temperature thing because on feature list temperature controlled fan on/off was advertised. But if 2A (if you have patience to wait then even 1A) load can make fan to start because high temperature threshold is reached then what's the point of that feature? Well of course from china all kinds of scam could come. Therefore I would like to know if such temperature at such load simply means that I've got bad unit or is it physically impossible to design a high frequency transformer that is around 5x5x5 cm in size and that stays cool under 2A load?

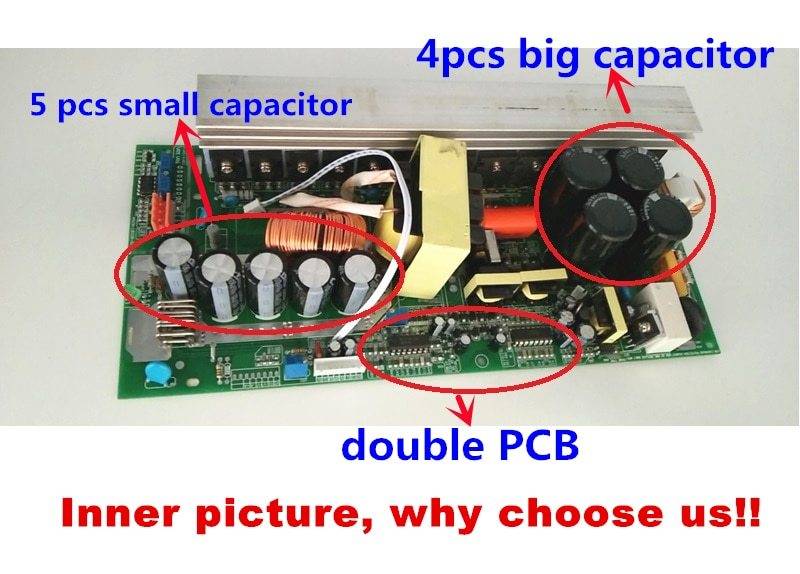

Below is also a product image. If this power supply at such size (29x13x7cm) were well designed what do you think how much current/power would it be realistic to draw from it without need for fan to start spinning (lets say the threshold is 50C for both transformer and heatsink and whatever gets there first starts the fan)?

I have question about high frequency transformers inside switch mode power supplies (SMPS). Is it normal for them to become hot under no load or low load? For example if power supply is rated for 144A at 13.8V and I only pull from it 2A at 9.6V, it normal that transformer becomes about 50C just in about 10 minutes or should it stay at room temperature at that low load? The size of transformer is roughly 5x5x5 cm. Or does it mean that something is wrong with transformer? Also, when load is less than 1A transformer starts to make high pitch (around 10-12 kz I think, can't measure it) whistling noise - is this normal or is it sign of low quality cheap PWM controller? When I increase the load the noise fades out - or what it seems like it just goes outside of human hearing range.

I am asking about this temperature thing because on feature list temperature controlled fan on/off was advertised. But if 2A (if you have patience to wait then even 1A) load can make fan to start because high temperature threshold is reached then what's the point of that feature? Well of course from china all kinds of scam could come. Therefore I would like to know if such temperature at such load simply means that I've got bad unit or is it physically impossible to design a high frequency transformer that is around 5x5x5 cm in size and that stays cool under 2A load?

Below is also a product image. If this power supply at such size (29x13x7cm) were well designed what do you think how much current/power would it be realistic to draw from it without need for fan to start spinning (lets say the threshold is 50C for both transformer and heatsink and whatever gets there first starts the fan)?