Makes sense, but I'm not sure what exactly to look for. Does the bias current define internal resistance in some way?

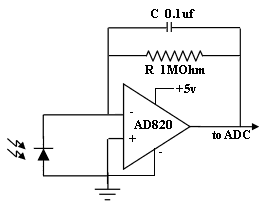

I use AD820, spec says input bias current is 2pA typical.

That's good enough.

I haven't noticed you suggesting using the same one he used.

If it's lt1012, then the spec says it have ten times more bias current.

What kind of noise would that be? Without the steppers i don't get any signs of noise.

Anything that is not supposed to be the desired signal is noise. Stepper motor controller, RF transmitter, florescent lights...anything.

Not really an issue of not wanting to redo it, but an issue of not wasting the effort for nothing - i want to know what causes what and how it should look like, then redo it properly and permanently.

It is my advice as a starting point. You want to start with a solid platform. I am sure you can make some ground connection and filtering and make it look better. But if you don't do the ground correctly, any accidental change in other area unrelated to the amp might cause the noise to come back. When I do this kind of design, I put in all the precaution at the beginning, I never have to spend time in fixing noise issue.

And i kind of like the idea of making the board as small as possible, putting it into a grounded box with the PD sticking out of that, and mount the whole thing onto the caret without any extra wires. But for that i need to know that i won't need to fiddle with it later.

There is never a guaranty on that, that's grounding for you. Read the long post I posted before, this is the hardest part. If I have my hands on the system, it would be 10 times easier. Just by looking at the picture is very hard.

Ok, if i understood this right.

The toroid (choke?) separates the ground "domains", so that shielding on the outside is not interfering with the shielding on the amp? Don't really understand how this is working - what is noise?

I am trying to isolate the amp and the diode. The only ground connection is from the battery and the output line. It is important that the PD and the shield of the input cable do not tough any of the metal in the system, that if you disconnect the connector of the battery input and the output line, you measure infinite resistance from the box to the rest of the system.

We want to avoid different parts of the "ground" side of the circuit from having different potentials?

Avoiding ground loop, I don't want any return current from other electronics go through the shield and the ground of the amp. I am trying to design the ground so there will be no other return path from other electronics. That's what cause the noise.

On the attempt:

I've wrapped the amp into duct tape, then into foil, grounded the whole thing to the amp's ground and added a choke at the wires going from it to the battery.

I've also wrapped most of the wire into the foil, not letting it touch any metal parts.

That's what it looks like now:

http://orbides.1gb.ru/orbf/inside_120228.jpg

If you make sure there is no contact to ground, it will do for now.

Apparently, i didn't understood it well, since now i get nonsense instead of noise.

Best described as a threshold - there is less noise, but there is either nothing or a swift climb into something if light is added. Before the "shielding" it was way more gradual.

I.e. it now responds to a very, very narrow range of currents from PD with the same output it had from a much wider range before.

What have i missed?