adishavit

- 5

- 0

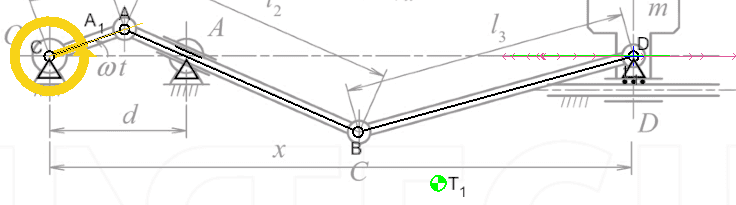

Say I have a mechanical device like this one:

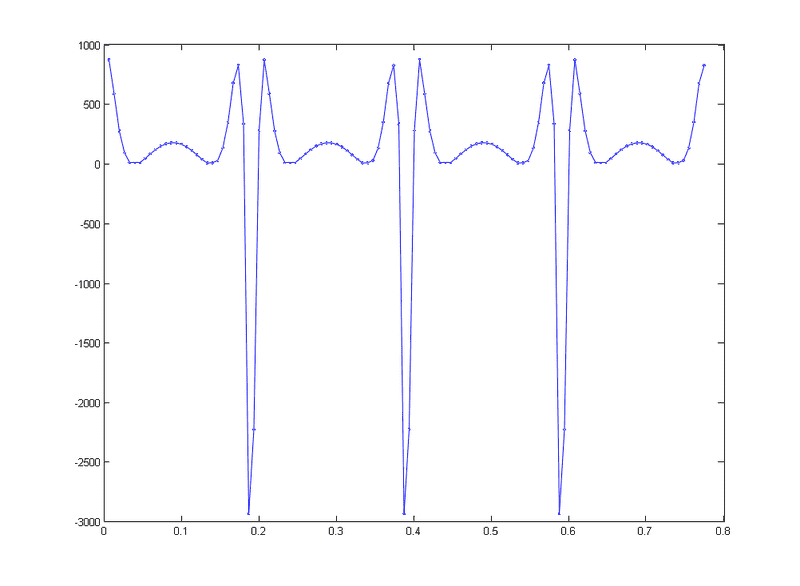

If I plot the acceleration profile at (trace-) point D I get something that looks something like this:

Now, here's the question:

Can I build a device composed of one of more (eccentric rotating mass) vibration motors that when rotating will approximate this acceleration profile?

Let us assume that they can be synchronized and initialized properly (as stepper motors can).

Ideally I'd like to have as few such motors as possible.

Maybe some DCT-like transform of the profile?

I'm not a-physicist nor a mechanical engineer, so be gentle.

If I plot the acceleration profile at (trace-) point D I get something that looks something like this:

Now, here's the question:

Can I build a device composed of one of more (eccentric rotating mass) vibration motors that when rotating will approximate this acceleration profile?

Let us assume that they can be synchronized and initialized properly (as stepper motors can).

Ideally I'd like to have as few such motors as possible.

Maybe some DCT-like transform of the profile?

I'm not a-physicist nor a mechanical engineer, so be gentle.