badharley99

- 2

- 0

Hi,

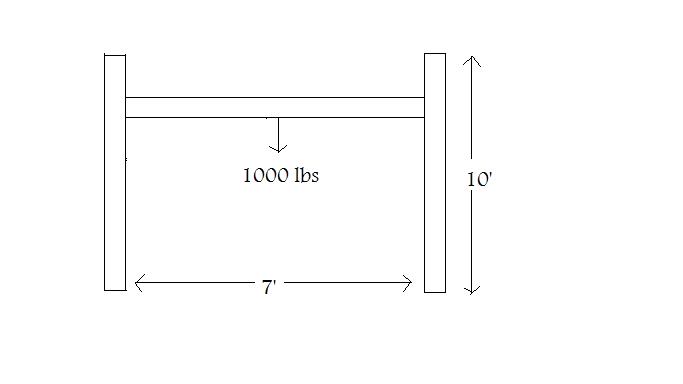

I need a little help on figuring out what size square tubing and thickness I need to make a basic lift for taking the body of a car on and off of a frame. I have included a small drawing of what I am trying to build.

I am going to need to support a maximum of 1000 pounds. All off the force will be vertical with no side loading.

The two vertical post will be bolted to the floor and attached to the ceiling. The distance between posts will be 7 feet. The load will be lifted directly in the middle of the horizontal tube.

Can you please help with what size square (or rectangle) tubing and thickness I need for the verticals and the horizontal to support this weight? Would it be better to use rectangular tubing for the horizontal?

I understand moments of inertia, Youngs modulus have to be figured in just having a little trouble.

Thank you

Nick

badharley99@yahoo.com

I need a little help on figuring out what size square tubing and thickness I need to make a basic lift for taking the body of a car on and off of a frame. I have included a small drawing of what I am trying to build.

I am going to need to support a maximum of 1000 pounds. All off the force will be vertical with no side loading.

The two vertical post will be bolted to the floor and attached to the ceiling. The distance between posts will be 7 feet. The load will be lifted directly in the middle of the horizontal tube.

Can you please help with what size square (or rectangle) tubing and thickness I need for the verticals and the horizontal to support this weight? Would it be better to use rectangular tubing for the horizontal?

I understand moments of inertia, Youngs modulus have to be figured in just having a little trouble.

Thank you

Nick

badharley99@yahoo.com