jstluise

- 58

- 0

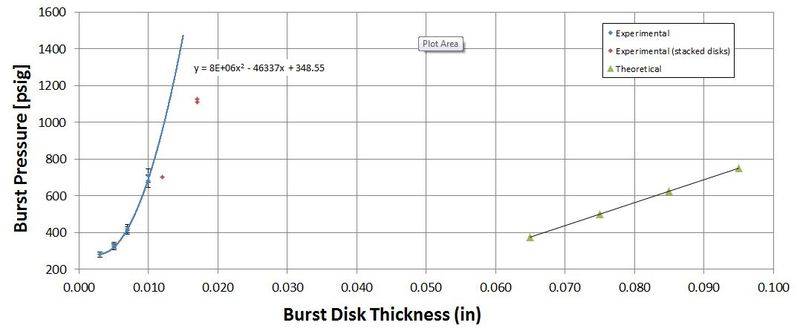

We have built a cold gas cannon that utilizes burst disks as the means to quickly release the built up pressure with maximum flow. The bore for the burst disk is 2" and the material is Brass 260 H02 (1/2 Hard). The disks are solid and flat (i.e. no scoring or features to promote a certain type of failure). The only thing that varies is the thickness of the disks, and that determines the bursting pressure.

In calculating the theoretical bursting pressures, I found this problem to be exactly like the "circular plate, uniform load, edged clamped" as seen on this website: (http://www.roymech.co.uk/Useful_Tables/Mechanics/Plates.html). As expected, the max stress occurs at the edges of the plate.

I calculated the theoretical disk thicknesses based on the bursting pressures we want to use. I found the theoretical thicknesses to be very high just based on intuition and a couple papers I've seen about burst disks. I also did some quick FEA in Solidworks, and the results mostly agreed with my calculations. We considered all of this and used much thinner disks when we started actual testing/calibration.

After the initial testing, we found we needed much thinner burst disks (compared to theoretical) to achieve the bursting pressures we wanted. Here is a plot comparing experimental to theoretical:

I saw on the website it says, "The equations are only valid if the deflection is small compared to the plate thickness." I thought this might be my problem but my calculated defection is only 10-20% of my plate thickness. Maybe that is still too big.

Does anyone have some thoughts on why the two do not agree?

In calculating the theoretical bursting pressures, I found this problem to be exactly like the "circular plate, uniform load, edged clamped" as seen on this website: (http://www.roymech.co.uk/Useful_Tables/Mechanics/Plates.html). As expected, the max stress occurs at the edges of the plate.

I calculated the theoretical disk thicknesses based on the bursting pressures we want to use. I found the theoretical thicknesses to be very high just based on intuition and a couple papers I've seen about burst disks. I also did some quick FEA in Solidworks, and the results mostly agreed with my calculations. We considered all of this and used much thinner disks when we started actual testing/calibration.

After the initial testing, we found we needed much thinner burst disks (compared to theoretical) to achieve the bursting pressures we wanted. Here is a plot comparing experimental to theoretical:

I saw on the website it says, "The equations are only valid if the deflection is small compared to the plate thickness." I thought this might be my problem but my calculated defection is only 10-20% of my plate thickness. Maybe that is still too big.

Does anyone have some thoughts on why the two do not agree?