JGrant

- 12

- 0

Hello,

It's been a while since I did this in college and I cannot remember a few steps.

I am trying to calculate the maximum force my designed shaft can handle before bending/shearing.

My shaft material is C1018 steel rod, with a yield strength of 53.7 KSI and an ultimate strength of 63.8 KSI. It will be rotating at 1650 RPM with 1/11HP. The end where I would have bending is necked down to fit into another part. It has been determined that the motor shaft will be the weakest link.

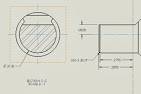

Here is a section of the shaft end. The rotating part will be in contact is the shaft over the .2795" dimension. With a force pushing down over that distance.

The area of the cross section is .06331 inches^2.

The overall shaft length is 3.527"

The shaft will be supported at .586" and 3.287" from the left.

Im mainly looking for help on how to calculate the force to bend this shaft.

If someone can just let me know how to calculate it, Id be very much appreciative.

Thank you.

It's been a while since I did this in college and I cannot remember a few steps.

I am trying to calculate the maximum force my designed shaft can handle before bending/shearing.

My shaft material is C1018 steel rod, with a yield strength of 53.7 KSI and an ultimate strength of 63.8 KSI. It will be rotating at 1650 RPM with 1/11HP. The end where I would have bending is necked down to fit into another part. It has been determined that the motor shaft will be the weakest link.

Here is a section of the shaft end. The rotating part will be in contact is the shaft over the .2795" dimension. With a force pushing down over that distance.

The area of the cross section is .06331 inches^2.

The overall shaft length is 3.527"

The shaft will be supported at .586" and 3.287" from the left.

Im mainly looking for help on how to calculate the force to bend this shaft.

If someone can just let me know how to calculate it, Id be very much appreciative.

Thank you.

Last edited: