- #1

karabiner98k

- 90

- 12

Hello everyone,

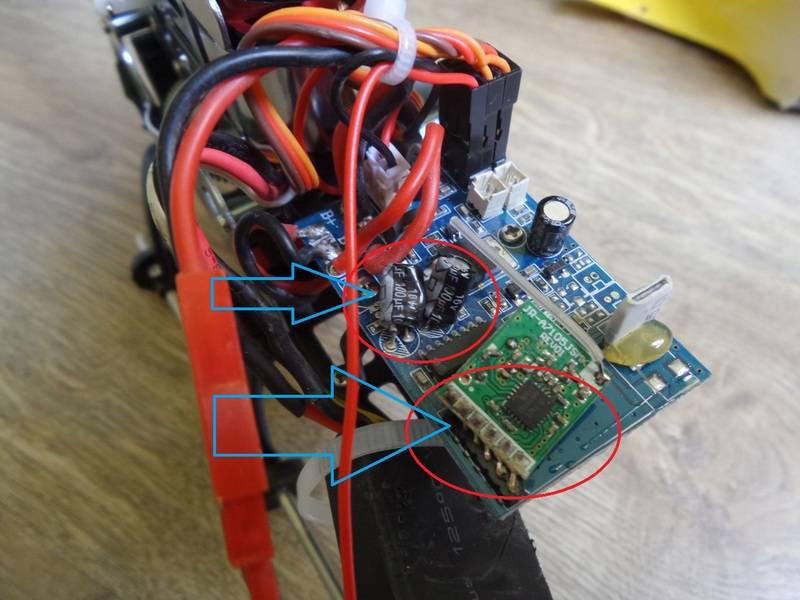

I have a RC helicopter that crashed recently and its receiver board was damaged.

Two capacitors were dented (as you can see in the picture) and the antenna base moved a bit.

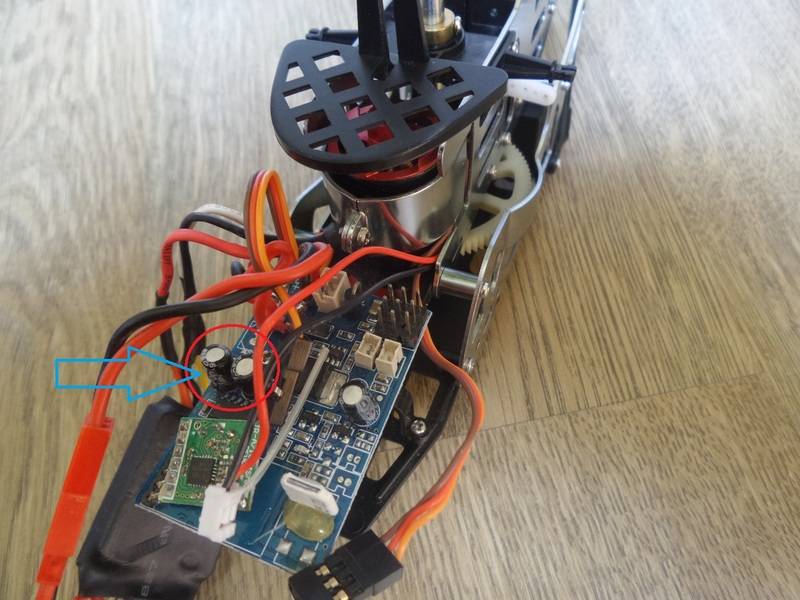

I straightened the capacitors which can be seen in the second picture.

After crash:

After my adjustments:

Despite the damages, the board works perfectly fine and there is no visible change in helicopter flight behavior.

It flies without any problems.

But the question I want to ask is that:

Is it OK to continue flying with this board and those capacitors?

I'm not an electronic expert, that's why I need your help.

Thanks in advance.

I have a RC helicopter that crashed recently and its receiver board was damaged.

Two capacitors were dented (as you can see in the picture) and the antenna base moved a bit.

I straightened the capacitors which can be seen in the second picture.

After crash:

After my adjustments:

Despite the damages, the board works perfectly fine and there is no visible change in helicopter flight behavior.

It flies without any problems.

But the question I want to ask is that:

Is it OK to continue flying with this board and those capacitors?

I'm not an electronic expert, that's why I need your help.

Thanks in advance.