Plasm47

- 10

- 0

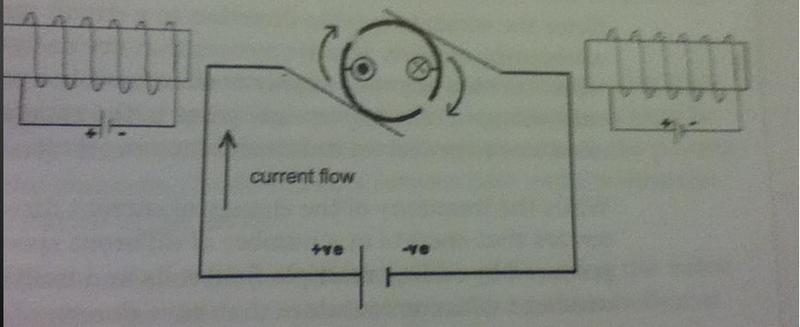

1. Small electric motors with only one armature loop sometimes get stuck. They can be started again by giving the armature a small twist. Looking at the diagram below, what might be the explanation for the motor not being able to start on its own?

When the brush(es) reaches the split within the ring, current ceases to flow. This lack of electricty will stop the split ring commutator and evidently, the motor. Since no current can be transmitted, the motor can't start on its own. However, giving the armature a small twist will close the circuit allowing the motor to operate.

Please help! I'm not really understanding the principles of motors. I'm taking shots in the dark in answering my questions.

When the brush(es) reaches the split within the ring, current ceases to flow. This lack of electricty will stop the split ring commutator and evidently, the motor. Since no current can be transmitted, the motor can't start on its own. However, giving the armature a small twist will close the circuit allowing the motor to operate.

Please help! I'm not really understanding the principles of motors. I'm taking shots in the dark in answering my questions.

Last edited: