harishree90

- 3

- 0

- TL;DR Summary

- Calculation of Exit Mass flow rate in a Plate Heat Exchanger to design a Cascade Heating Network

Hello All,

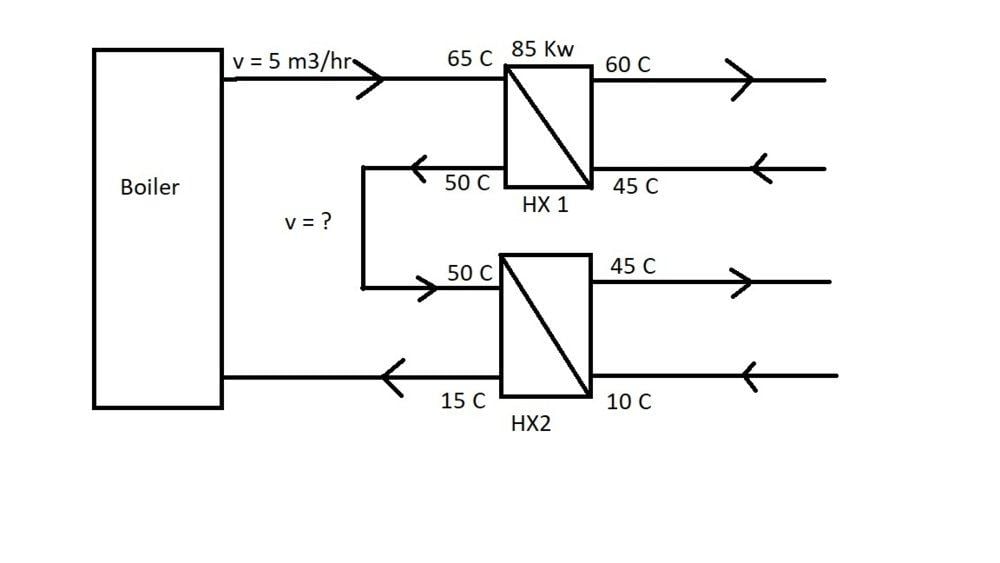

I am working on a project with plate heat exchangers connected in a cascade system to heat up water connections in a huge system

The Problem Statement :

A boiler produces and circulates hot water at 65 degC to a Heat Exchanger and come out at 50 degC, where as the other fluid is also water which needs to be heated to 60 degC from 45 degC , The volume flow rate of hot water is at 5.0 m3/hr and the dia meter of the pipe is DN50

Using energy Equilibrium , Heat transfer rate in the first heat exchanger

Q = m X Cp X ΔT which come around 85KW

now from the outlet of the Heat Exchange in the hot Side which is at 50 degC, I am connecting it as an Input to another heat Exchanger, which is also used to heat water from 10 degC to 45 degC and the hot water connected back to the Boiler which is at 15 degC

My question is, how can I calcuate the volume flow rate or mass flow rate or velocity of water at the outlet in the first heat exchanger which acts as an Input to second HX, so that I can calculate the heat transfer rate of the second HX to determine if need to have a pump in the circuit.

Thanks in Advance

If my question is not clear please let me know

I am working on a project with plate heat exchangers connected in a cascade system to heat up water connections in a huge system

The Problem Statement :

A boiler produces and circulates hot water at 65 degC to a Heat Exchanger and come out at 50 degC, where as the other fluid is also water which needs to be heated to 60 degC from 45 degC , The volume flow rate of hot water is at 5.0 m3/hr and the dia meter of the pipe is DN50

Using energy Equilibrium , Heat transfer rate in the first heat exchanger

Q = m X Cp X ΔT which come around 85KW

now from the outlet of the Heat Exchange in the hot Side which is at 50 degC, I am connecting it as an Input to another heat Exchanger, which is also used to heat water from 10 degC to 45 degC and the hot water connected back to the Boiler which is at 15 degC

My question is, how can I calcuate the volume flow rate or mass flow rate or velocity of water at the outlet in the first heat exchanger which acts as an Input to second HX, so that I can calculate the heat transfer rate of the second HX to determine if need to have a pump in the circuit.

Thanks in Advance

If my question is not clear please let me know