000kev000

- 2

- 0

just a quick question .

I'm thinking about building myself a vertical axis wind turbine and using the turbine to power a few lights around the house .

my question is about using a magnetic gearing system . and will it work (produce more power than just using the base of the turbine with attached magnets above a stationary stator )

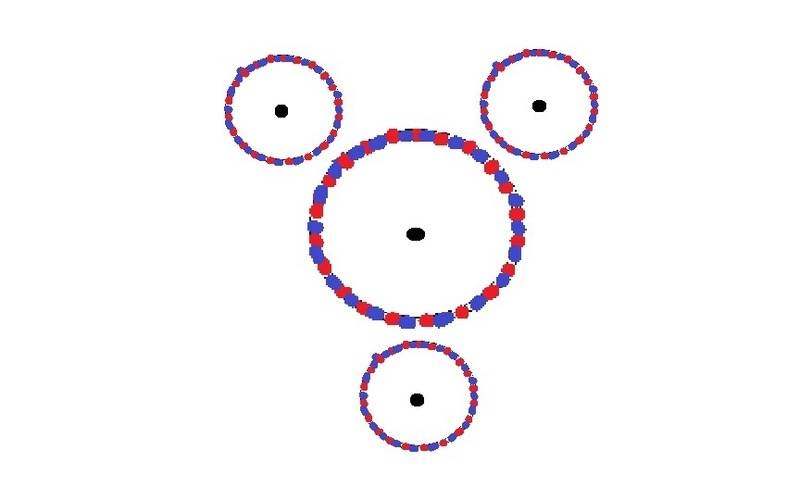

i've drawn a quick example of what I'm thinking about (it's rough but should show what i mean)

this was just a quick example using paint . the real thing will be using 32 neodymium magnets around the center wheel/gear and this will be the base of the tubine itself approx 1000mm/1m diameter

the outer wheel or wheels if possible will be exacty half the center . so 500mm/.5m diameter using 16 neodymium magnets . all four gears / wheels will be mounted using a mag lev bearing system reducing friction as much possible .

the aim is to have the three outer wheels spinning over stators

would the extra force required to turn the turbine be too much to make this model functual or would it work

I'm thinking about building myself a vertical axis wind turbine and using the turbine to power a few lights around the house .

my question is about using a magnetic gearing system . and will it work (produce more power than just using the base of the turbine with attached magnets above a stationary stator )

i've drawn a quick example of what I'm thinking about (it's rough but should show what i mean)

this was just a quick example using paint . the real thing will be using 32 neodymium magnets around the center wheel/gear and this will be the base of the tubine itself approx 1000mm/1m diameter

the outer wheel or wheels if possible will be exacty half the center . so 500mm/.5m diameter using 16 neodymium magnets . all four gears / wheels will be mounted using a mag lev bearing system reducing friction as much possible .

the aim is to have the three outer wheels spinning over stators

would the extra force required to turn the turbine be too much to make this model functual or would it work