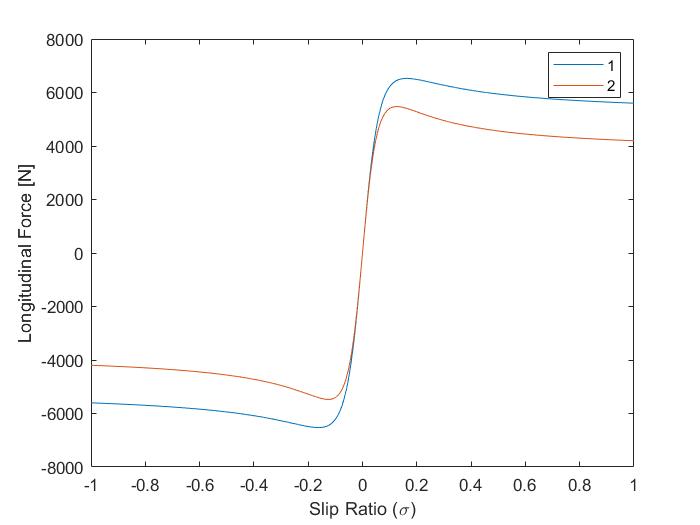

The discussion centers on the relationship between maximum slip ratio and the type of drivetrain, specifically front-wheel drive (FWD) versus rear-wheel drive (RWD). It highlights that FWD vehicles generally have better traction due to the engine's weight being over the front wheels, making them more effective in adverse conditions like snow and rain. However, RWD vehicles are noted for better performance during turns. The graph referenced illustrates that both drivetrain types can achieve the same maximum slip ratio, as slip is necessary to generate friction. Ultimately, the normal force acting on the tire is a more significant factor than whether the vehicle is FWD or RWD.