Huumah

- 27

- 0

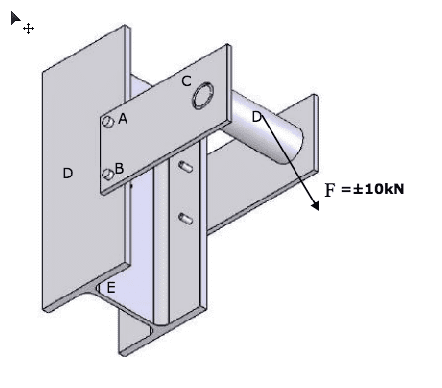

I'm trying my first design and want to make it successful before I actually make the product.

I want to calculate what the stresses are and where they are likely to be.

F is a varied load from -10 to 10 kN

To find the critical points, should I check the points that i labeled A, B , C , D ?

Which ones is most likely to have the most stress based on my design?

I want to calculate what the stresses are and where they are likely to be.

F is a varied load from -10 to 10 kN

To find the critical points, should I check the points that i labeled A, B , C , D ?

Which ones is most likely to have the most stress based on my design?