Trevordean

- 2

- 0

- TL;DR Summary

- is it possible to heat a coiled spring

Summary: is it possible to heat a coiled spring

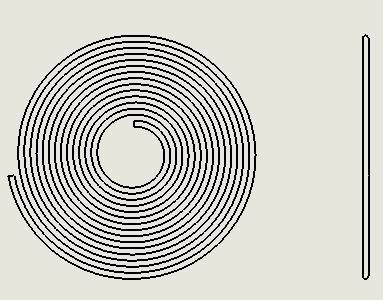

If I had a spirally coiled spring like inserted pic, spiral coiled spring approx. 300mm dia and spring section +-12mm dia with +-1mm gauge wire, with a total length of spring approx. 4mtr-6mtr , is it possible to heat this with induction heating generator, say similar to an induction geyser system? would the coil heat up evenly, if possible? can it be heated from one side of the coil or would you need 2 induction elements one either side or is it just not possible? any assistance with clearing this up will be appreciated.

If I had a spirally coiled spring like inserted pic, spiral coiled spring approx. 300mm dia and spring section +-12mm dia with +-1mm gauge wire, with a total length of spring approx. 4mtr-6mtr , is it possible to heat this with induction heating generator, say similar to an induction geyser system? would the coil heat up evenly, if possible? can it be heated from one side of the coil or would you need 2 induction elements one either side or is it just not possible? any assistance with clearing this up will be appreciated.