StealthRay

- 51

- 0

Hi,

I have 2 questions here and hope some experts can answer them.

Question 1:

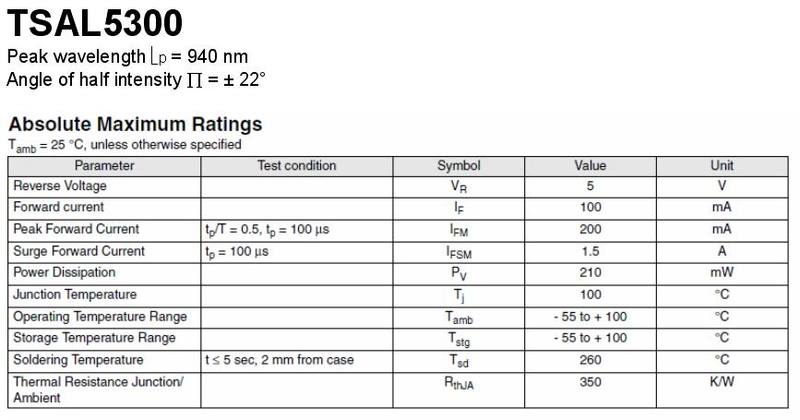

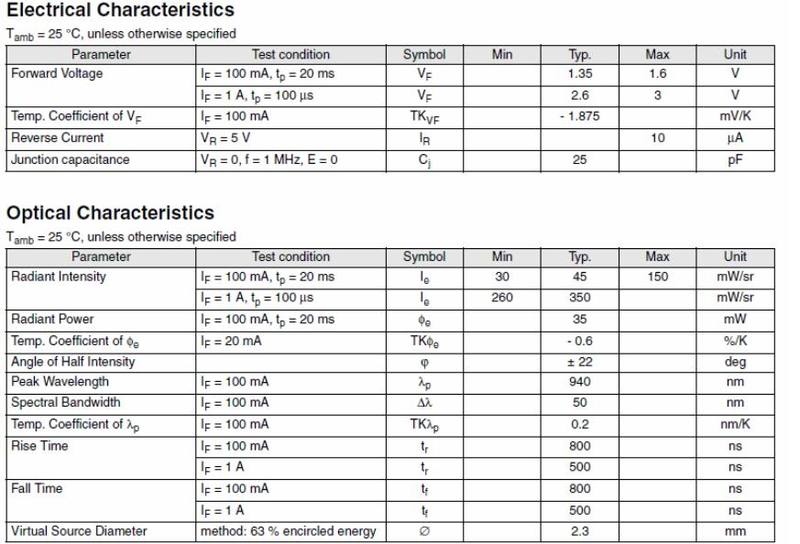

How to improve the signal distance of the IR led?What parameters in the datasheet that we should look into?

I have purchased few IR leds but all of them can't shoot more than 3 metres. I noticed increasing the current to the leds does increase the distance but not by much.The absolute max rating for IF is 100mA and I even pushed the current to this limit but didnt see any significant improvement.

Could it be because of the 950 nm wavelength of the led which limits the distance?

My project does not need signal to go above 1 metre but it would be better if I can get to know on the signal distance a little bit more.

Question 2:

I am using Omron PLC CPM-2 version to control my project.Although I have successfully produce a working program for the project,there are certain sequences of inputs which can crash the program.Of course I tried my best to physically avoid having multiple inputs all at once but sometimes the IR signal accidentally hit few receivers and crash the programs.

Once the program crash,there is no way to have it work normally and it usually stuck at certain output.

Methods which I tried to reset the PLC but to no avail;

1)Clearing all memory which usually ended with PLC error.

2)Transfer the program to PLC again.

3)Switch to program mode,monitor mode and run mode.

4)Switch off and on the PLC.

Sometimes,the PLC get back to running after I click here and there but I am not sure the way to reset the PLC.Today,after numerous unsuccessful reset,I had to change to another PLC.

Although I managed to produce the program which work in the sequence I want,I find it rather hard to fix the crash.

For example,Input 1 produces the output sequence 1.Next input 2 produces the output sequence 2 and so on.If I play with the inputs such as on and off input 1,2,3,4,5 randomly,the program could crash.

So the best way I can do now is to reset the PLC everytime it crashes and try to avoid having random inputs all at once.

Thank you.

P/S:Sorry for the lengthy questions

I have 2 questions here and hope some experts can answer them.

Question 1:

How to improve the signal distance of the IR led?What parameters in the datasheet that we should look into?

I have purchased few IR leds but all of them can't shoot more than 3 metres. I noticed increasing the current to the leds does increase the distance but not by much.The absolute max rating for IF is 100mA and I even pushed the current to this limit but didnt see any significant improvement.

Could it be because of the 950 nm wavelength of the led which limits the distance?

My project does not need signal to go above 1 metre but it would be better if I can get to know on the signal distance a little bit more.

Question 2:

I am using Omron PLC CPM-2 version to control my project.Although I have successfully produce a working program for the project,there are certain sequences of inputs which can crash the program.Of course I tried my best to physically avoid having multiple inputs all at once but sometimes the IR signal accidentally hit few receivers and crash the programs.

Once the program crash,there is no way to have it work normally and it usually stuck at certain output.

Methods which I tried to reset the PLC but to no avail;

1)Clearing all memory which usually ended with PLC error.

2)Transfer the program to PLC again.

3)Switch to program mode,monitor mode and run mode.

4)Switch off and on the PLC.

Sometimes,the PLC get back to running after I click here and there but I am not sure the way to reset the PLC.Today,after numerous unsuccessful reset,I had to change to another PLC.

Although I managed to produce the program which work in the sequence I want,I find it rather hard to fix the crash.

For example,Input 1 produces the output sequence 1.Next input 2 produces the output sequence 2 and so on.If I play with the inputs such as on and off input 1,2,3,4,5 randomly,the program could crash.

So the best way I can do now is to reset the PLC everytime it crashes and try to avoid having random inputs all at once.

Thank you.

P/S:Sorry for the lengthy questions