WhiskeyHammer

- 8

- 0

I have an application involving a spring and in order to get the proper behavior, I need to solve the problem below. I've been at it for weeks and haven't been able to solve it - which tells me its time to appeal to my mathematical betters.

Given a spring that exerts 36.6lbs of force(N) while being compressed to 20% of its available deflection, find the combination of active coils(a) and wire diameter(d) that achieves the greatest force when the spring is compressed to %80 of its avilable deflection.

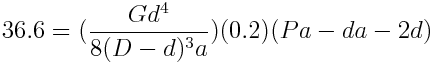

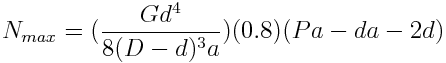

So basically I've boiled it down to the two values I need to solve for for each compression:

The closest I've come to something that makes sense is to solve for the first equation (the spring at 20%) in terms of a. Then Rework the second equation with th new value for a. However this seems to produce nonsense when graphed.

If its relevant the values for the other variables are as follows:

If you need/want to see how I arrived at any of the above conclusions let me know and Ill put it up.

Given a spring that exerts 36.6lbs of force(N) while being compressed to 20% of its available deflection, find the combination of active coils(a) and wire diameter(d) that achieves the greatest force when the spring is compressed to %80 of its avilable deflection.

So basically I've boiled it down to the two values I need to solve for for each compression:

The closest I've come to something that makes sense is to solve for the first equation (the spring at 20%) in terms of a. Then Rework the second equation with th new value for a. However this seems to produce nonsense when graphed.

If its relevant the values for the other variables are as follows:

- G= 11.5x10^6

- D= 0.269

- P= tan(12degrees)Pi(D-d)

If you need/want to see how I arrived at any of the above conclusions let me know and Ill put it up.