Scott Q

- 3

- 0

Hello Everyone,

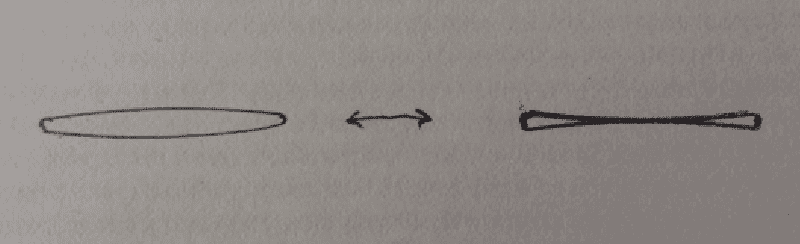

I'm looking for a sealing membrane, or comparable solution, to seal a thin opening (~15mm x 2mm) that oscillates elliptically, like in my example picture below, with a low amplitude (+/- 1mm) and frequency in the 100s - 1000s of Hz range.

Any ideas?

I'm looking for a sealing membrane, or comparable solution, to seal a thin opening (~15mm x 2mm) that oscillates elliptically, like in my example picture below, with a low amplitude (+/- 1mm) and frequency in the 100s - 1000s of Hz range.

Any ideas?