DaveC426913

Gold Member

2025 Award

- 24,342

- 8,543

- TL;DR

- Trying to figure out a practical way of making altitude layers for this relief map

I hope to make a 3D relief model of my town and environs.

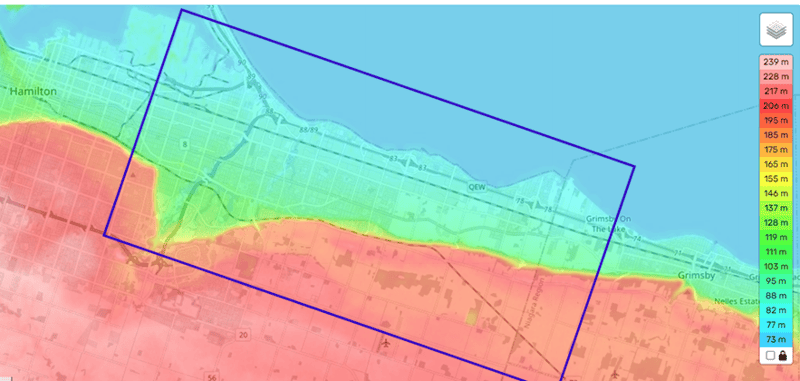

First, rough idea, it will be 1m by 0.5m at 1:10,000. That will give me a map of the area 10km by 5km. Sort of this-ish:

As you can see, it's quite flat here, both abov e and below the escarpment. If I were to keep the vertical scale, that would make the plateau ("the mountain" is what it's called here) only 1.5cm high, and the rest would be as flat as a pool table. So I might boost the vertical scale by 5 or so. Even that gives me a total height of only 7.5cm.

(I haven't decided yet whether I want to smooth out the contours or leave them stepped.)

What I am trying to do is figure out how I can build the relief economically, cost- and effort-wise.

My first attempt was to cut out the altitude contours from sheets. At 150m, I might settle on 10m contours, which would make for 15 or so layers, each .5cm high.I printed out the contour maps of the area and glued then into foam core, and cut along the contour lines. That did not go nearly as well in reality as it did in my head. Even with an Xacto knife, the edges were mangled and the paper cut very poorly. I tried a hobby saw (just a toothed wire held taut between prongs) and that went poorly. I tried a hot wire, which also went poorly.

So I tried balsa sheets. This went pretty poorly too. I have to use the Xacto knife to saw, so I get a pretty rough, faceted edge.And there's yet another problem: Half my map is going to be 7.5cm thick and solid. That's a lot of material - and at quite a cost. I considered hollowing out everything under the mountain but - while that may save me some weight - it doesn't really save me materials. I just end up discarding a lot of it.

It's too big to 3D print, so I'm trying to do some lateral thinking and seeing if there's any methods I haven't thought of.

First, rough idea, it will be 1m by 0.5m at 1:10,000. That will give me a map of the area 10km by 5km. Sort of this-ish:

As you can see, it's quite flat here, both abov e and below the escarpment. If I were to keep the vertical scale, that would make the plateau ("the mountain" is what it's called here) only 1.5cm high, and the rest would be as flat as a pool table. So I might boost the vertical scale by 5 or so. Even that gives me a total height of only 7.5cm.

(I haven't decided yet whether I want to smooth out the contours or leave them stepped.)

What I am trying to do is figure out how I can build the relief economically, cost- and effort-wise.

My first attempt was to cut out the altitude contours from sheets. At 150m, I might settle on 10m contours, which would make for 15 or so layers, each .5cm high.I printed out the contour maps of the area and glued then into foam core, and cut along the contour lines. That did not go nearly as well in reality as it did in my head. Even with an Xacto knife, the edges were mangled and the paper cut very poorly. I tried a hobby saw (just a toothed wire held taut between prongs) and that went poorly. I tried a hot wire, which also went poorly.

So I tried balsa sheets. This went pretty poorly too. I have to use the Xacto knife to saw, so I get a pretty rough, faceted edge.And there's yet another problem: Half my map is going to be 7.5cm thick and solid. That's a lot of material - and at quite a cost. I considered hollowing out everything under the mountain but - while that may save me some weight - it doesn't really save me materials. I just end up discarding a lot of it.

It's too big to 3D print, so I'm trying to do some lateral thinking and seeing if there's any methods I haven't thought of.